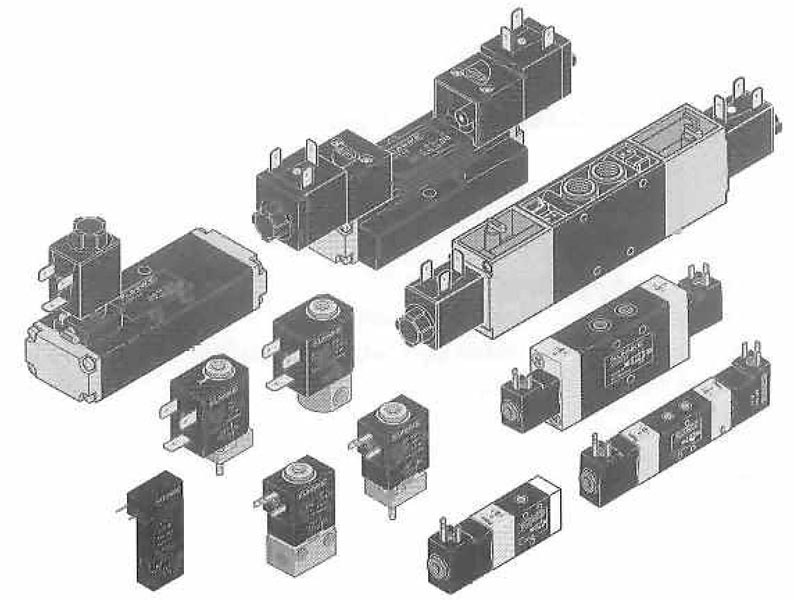

Pneumatic Valves

Pneumatic valves are one of the components responsible for regulating the pressure, rate, and amount of air that circulates throughout a pneumatic system. Ellis Kuhnke Controls has been in business since 1962. If you need Pneumatic Valves then we are your experts.

Tips For Picking Out Pneumatic Valves

Pneumatic systems are extensively used in a multitude of industrial applications. To have a functional pneumatic system, you must use the right products; you have to know which pneumatic valve to use in a specific scenario, as not all valves are applicable in the same process. Understanding how a pneumatic valve works is the first step to determining what requirements are necessary for your pneumatic system. Make sure you take the time to fully understand your system and what you need before making any purchases. Below is an accumulation of some common tips that can help to construct the perfect pneumatic system.

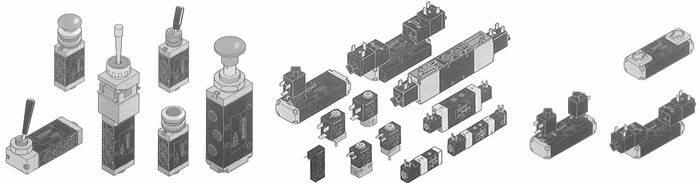

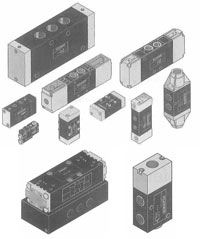

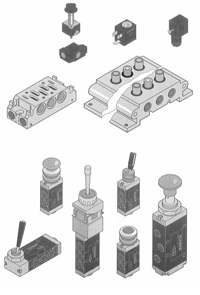

Pneumatic valves

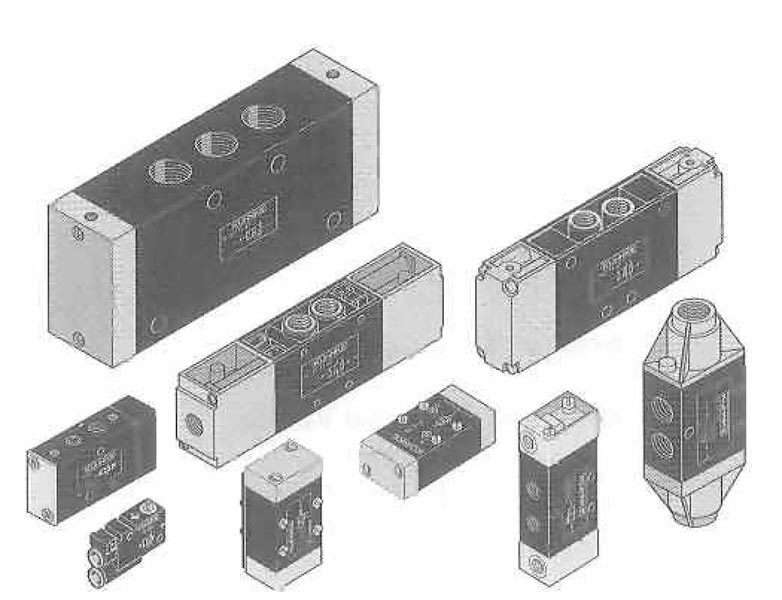

Most valves are used in light-duty and low-pressure applications. An automated flow is created through the opening and closing of a valve. Compressed air causes the valve to either open or close, which allows air to move through the pneumatic system. Whether it opens or closes depends on the specific design of the valve itself, and the application that utilizes it.

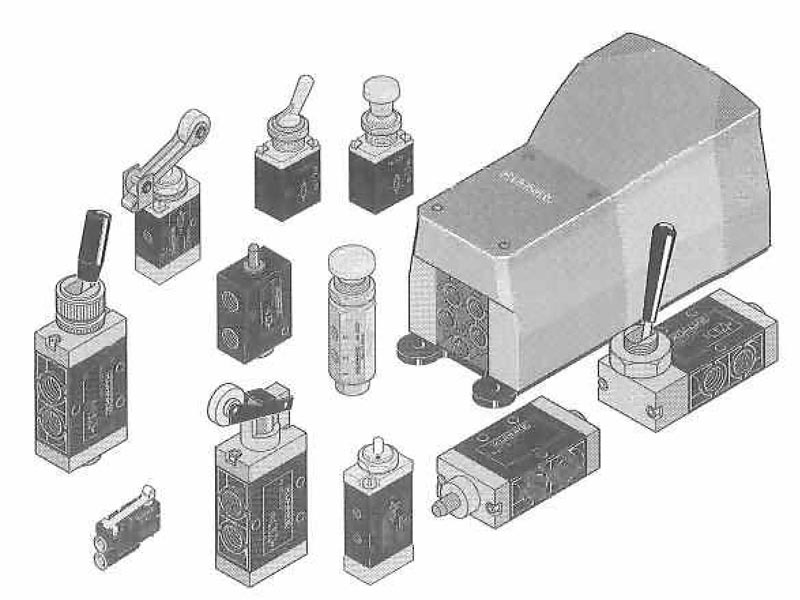

Flow Direction and Flow Speed:

In order to pick the correct valve, you need figure out whether you want to regulate flow direction, or flow speed. To control flow direction, you need to install a flow direction valve that will determine the airflow direction. If you are looking to control speed, a proportional valve will help the flow rate down a given path.

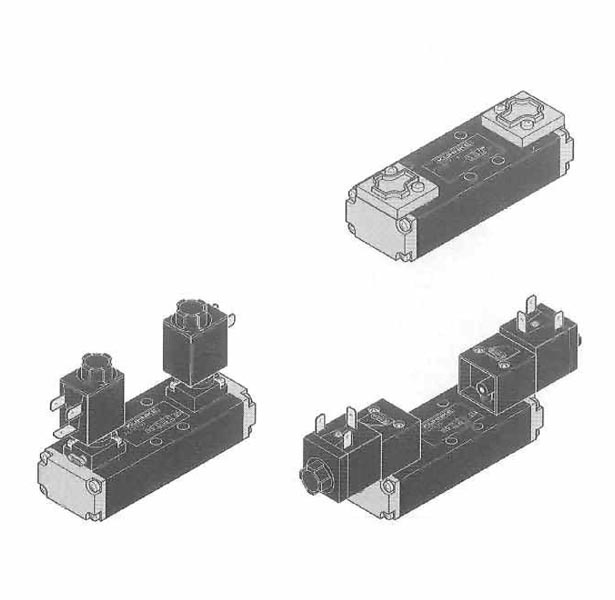

Directional Pneumatic Valves

Directional valves are used to control flow within the system. The desired action of your system will determine the type of valve needed. There are three different types of popular directional valves:

Directional valves are used to control flow within the system. The desired action of your system will determine the type of valve needed. There are three different types of popular directional valves:

- Two-way valves: Two-way valves allow or stop flow of air and provide an on/off function in the circuit.

- Three-way valves: Three way valves contain three passages, which are used to pressurize and exhaust a port.

- Four-way valves: Four way valves are one of the most commonly utilized components for directional control in a pneumatic system. The four valves make it easy to change the motion of a cylinder, motor, or alternative powering component.

Inputs and Outputs

Determine the number of inputs and outputs on your directional valves. The common directional valve has a standard number of three openings; two of which are outputs, and the remaining is for an input.

Related Reading about Pneumatic Valves

- Directional Control for Pneumatic Valves

Before you use any pneumatic valves for your applications, it is important to understand the basics of how they work.

- Different Types of Pneumatic Valves

Pneumatic valves are just one type pneumatic control that we sell. There are many different types of valves for different systems; however, they are all designed to control rate, pressure, and amount of air that goes in and out of a pneumatic system.

- Using Pneumatic Valves Properly

If your company works with pneumatic circuits, then the use of pneumatic valves is essential. There are many different pneumatics valves to choose. The guidelines for instruction will depend on the model you are using.

- The Basics of Pneumatic Valves

Purchasing pneumatic valves can seem like a daunting task for business owners. There are so many options to choose. There are a lot of phrases and terminology to know.

- Pneumatic Valve Configurations

One of the most basic types of systems and applications found in pneumatic valves are flow control valves. These type of valves are used in several different ways, and they offer two configurations.

- Brief history of Pneumatics: From Blowguns to Pneumatic Valves & Pneumatic Controls

- Frequently Asked Questions: Pneumatic Valves

- A Great Combination: Pneumatic Actuator, Pneumatic Timer, Pneumatic Valves, and Pneumatic Indicators

- Valve Directional-Control

- Flow Control Valves

- Types of Pneumatic Flow Control Valves

- Pneumatic Systems and Safety

- Advantages of Pneumatic Systems

- Directional Control Valves

- Tips for Selecting Directional Pneumatic Valve Controls

- Safety and Pneumatic Valves

- Using Pneumatic Solenoid Valves

- Advantages of Total Pneumatic Control

- What is a Pneumatic Flow Control Valve?

- Safety and Pneumatic Actuators.

- Air Preparation and Pneumatic Valves

- Safety While Using Pneumatic Systems and Tools

- Basics of Directional Control Valves

- Controling Pneumatic Energy

- Guide for Using Miniature Solenoid Valves

- Basic Valves Designs

- Understanding Solenoid Valves

- Reasons to Use Miniature Solenoid Valves

- Considerations for Pneumatic Valves

- Using Pneumatic Systems instead Hydraulics

- Pneumatic Valve Operational and Performance Specifications

- Understanding Basic Pneumatic Valve Functionality

- Common Functions of Pneumatic Valves

- Why Pneumatic Systems are Essential for Modern Automation

- Tips for Effectively Using Pneumatic Controls

- Common Pneumatic Valve Types

- Why do so Many Use Pneumatic Control Systems?

- Common Valve Categories

- Keeping Costs Down when Using Pneumatic Control Systems

- Tips for Reducing Noise from Pneumatic Control Systems

- What are Some Non-Traditional Pneumatic Valve Types

- What are Common Pneumatic Valve Types

- What is a Pneumatic Valve?

- Non-Traditional Flow Control Valves

- Ellis/Kuhnke Controls

132 Lewis Street Unit A-2, Eatontown, N.J. 07724

Phone: 1-800-221-0714

Fax: 732-291-8154

Email: Info@ekci.com

- Home Pneumatic Controls Technical Info CAD Drawings Contact Us Pneumatic Timers Blog Site Map