Common Valve Categories

Directional control valves are used to start, change, and stop the direction of flow compressed air in pneumatic systems. It is common to find manufacturing companies benefiting from compressed air as a power source to operate equipment and tools. For many businesses, pneumatic controls and pneumatic valves are essential for daily operations. It is important to understand that different applications are possible through different types of compressed air valves.

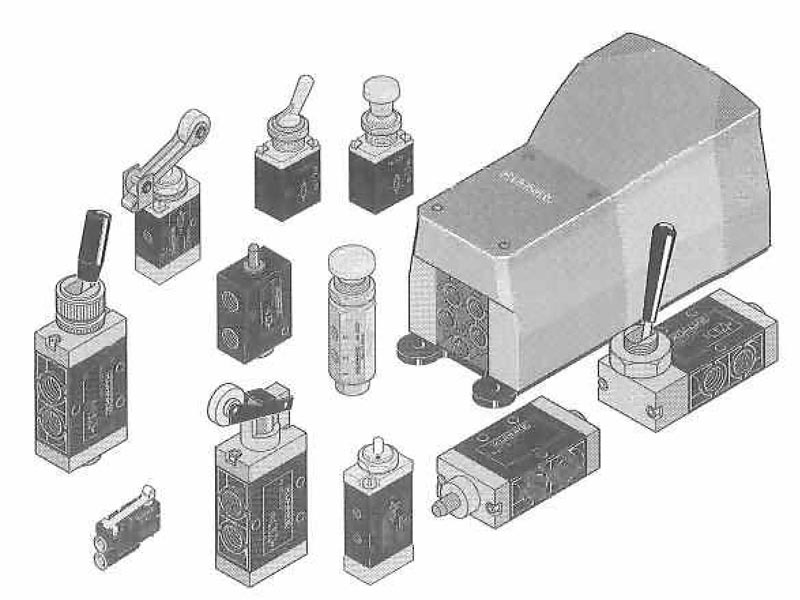

Valves have been designed to meet the requirements of specific applications in a factory setting. It is important to remember that different valves are suited for jobs. Pneumatic valve designs are typically broken up into several categories: poppet, spool-bonded, lapped, sliding seal, diaphragm, and rotary. Spool bonded, spool lapped, and popper valves are the most used designs.

Pneumatic Valves

A bonded spool valve uses elastomers to protect against pressure. Bonded spools are commonly used because they offer practically no leakage, while also being able to be used in three-position applications. The valves go through the blocked center that prevents blowby our of exhaust ports when flow patterns change.

A poppet valve works with a large poppet seal, and it operates in a way that is like a home’s water faucet. Seal surfaces I a poppet valve moves in a perpendicular path to the valve area. It also pushes against an annular ridge to create positive sealing. Use poppet valves when you need a rugged, fast, and reliable value that works in adverse conditions.

Spool valves come in 4-way and 3-way configurations. 3-way spools are often used as a 2-way valve.

Pneumatic Valves

- Tips for Effectively Using Pneumatic Controls

Pneumatic valves, for many, are necessary components that are tasked with controlling the rate, pressure, and the total amount of air moving through a pneumatic system.

- Common Pneumatic Valve Types

- Why do so Many Use Pneumatic Control Systems?

- Ellis/Kuhnke Controls

132 Lewis Street Unit A-2, Eatontown, N.J. 07724

Phone: 1-800-221-0714

Fax: 732-291-8154

Email: Info@ekci.com

- Home Pneumatic Controls Technical Info CAD Drawings Contact Us Pneumatic Timers Blog Site Map