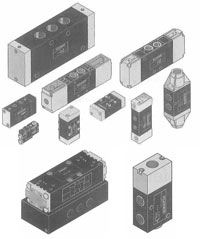

Basic Valves Designs

When selecting directional controls for pneumatic valves, it is important to consider basic valve design. Poppet-types elements can accomplish the sealing function of a valve. Shear-action valves can control the flow by using parts that slide across flow paths. For this process, four basic types include packed spool, lapped spool, packed bore, and sliding plate. For the sliding plate variant, the disc uses unbalanced pressure to force mechanisms to seal against mating surfaces. The goal is to control air flow from the desired port while sealing flow from others. Designs are constructed in 2, 3, and 4-way action.

Other types of valves (shear-action) incorporate spools for moving parts. In most cases, a spool will stroke against a metal bore. A packed spool value is strong and has resilient seals that are fitted around spool lands: to create close to leak-proof sealing.

A packaged-bore pneumatic valve is another common directional valve. It has metal spools that work with bore fittings. It is paired with several stationary seals, which create isolation between ports. A lapped-spool valve is frequently referred to as a shear-action type. For this design, it mostly depends on the ability for a close fit between the bore and the spools (without using seals). The purpose of this design to allow for better control of air that is flowing between ports. This design is popular because it does not create bubbles, as a result of the tight seal.

Pneumatic Valves

For more information on acquiring the right pneumatic devices, please give us a call. We carry a full line of pneumatic times, pneumatic indicators, and more.

Related Reading:

- Safety and Pneumatic ActuatorsKeep your factory safe when using pneumatic systems. Our team can help you acquire the correct pneumatic tools for you and your business.

- Air Preparation and Pneumatic Valves

- Safety While Using Pneumatic Systems and Tools

- Basics of Directional Control Valves

- Ellis/Kuhnke Controls

132 Lewis Street Unit A-2, Eatontown, N.J. 07724

Phone: 1-800-221-0714

Fax: 732-291-8154

Email: Info@ekci.com

- Home Pneumatic Controls Technical Info CAD Drawings Contact Us Pneumatic Timers Blog Site Map