Pneumatic Valve Operational and Performance Specifications

How does one know when they are choosing the correct pneumatic valve for their pneumatic system? Utilizing wrong components can have detrimental effects on the operation of systems. Pneumatic valves are frequently considered as the last component in a pneumatic system. Valve specifications are best determined when desired parameters for applications—load, force, and speed—are known. It is also important to first know any special application needs. Knowing the above information allows users to purchase correct cylinder sizes and downstream of valves.

Users that follow two necessary steps when outlining valve selections will end up with better performing valves for their system.

First, identify the primary function needed from your new pneumatic valve. How many ports do you need? The most common amount of ports are 3, 4, and 5. You also must ask and answer, how many valve positions will be required? Although there are other options, most frequently valves have 2 or 3 positions that offer systems unique directional flow paths. Finally, ask about the functionality of the directional control valve.

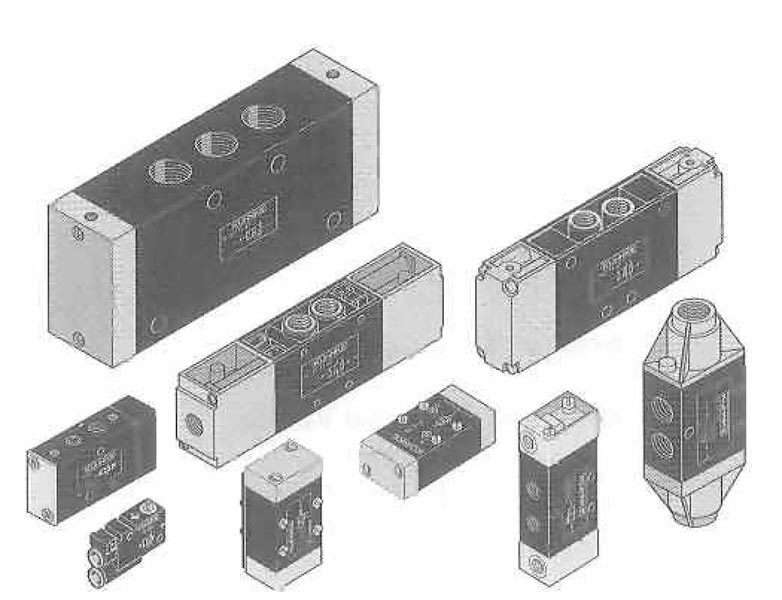

Pneumatic Valves

After addressing the above questions, it is possible to move to step two, which seeks to understand operational and performance specifications. Answer questions like:

- How quick should response time be for the valve to shift?

- What is the amount of flow needed for supporting downstream work?

- What are your connection and power requirements?

- Will you need any specific valve specifications or any optional features?

Going slowly through both steps and answering these questions will help a user to determine the kind of valve that will work in their system. For any extra information on pneumatic control systems, let us be your first call.

Related Reading:

- Understanding Solenoid Valves

Electromechanical solenoid valves allow for effective, automatic control of fluid flow controls for air, gas, liquid, or steam. The valves use magnetic fields to regulate the opening and flow of fluid in a calve.

- Reasons to Use Miniature Solenoid Valves

- Considerations for Pneumatic Valves

- Using Pneumatic Systems instead Hydraulics

- Ellis/Kuhnke Controls

132 Lewis Street Unit A-2, Eatontown, N.J. 07724

Phone: 1-800-221-0714

Fax: 732-291-8154

Email: Info@ekci.com

- Home Pneumatic Controls Technical Info CAD Drawings Contact Us Pneumatic Timers Blog Site Map