Pneumatic vs Electronic Timers for Hazardous Areas: Safety and Performance Compared

Industries that handle flammable gases, vapors, or dust must use equipment that will not ignite the atmosphere. Controlling time delays in such hazardous areas is challenging because many timing devices rely on electrical power. When choosing between pneumatic and electronic timers, including pneumatic timers, safety and precision must be carefully balanced. Engineers need to understand how each technology performs in hazardous environments and the trade-offs it entails.

Examining the characteristics of pneumatic and electronic timers for use in hazardous areas highlights their advantages and limitations, as well as the selection criteria. Recognizing these distinctions enables designers to choose the technology that best suits their application while meeting safety and performance requirements.

What Makes an Environment Hazardous

The presence of ignitable concentrations of gases, vapors, or combustible dusts defines hazardous areas. Standards such as NFPA 70 and IEC 60079 classify these locations into zones or classes based on frequency and duration of exposure. Equipment used in these zones must prevent ignition through intrinsic safety, explosion-proof enclosures, or other protective measures. Failure to comply can lead to explosions, injuries, and regulatory penalties.

How Pneumatic Timers Function in Hazardous Areas

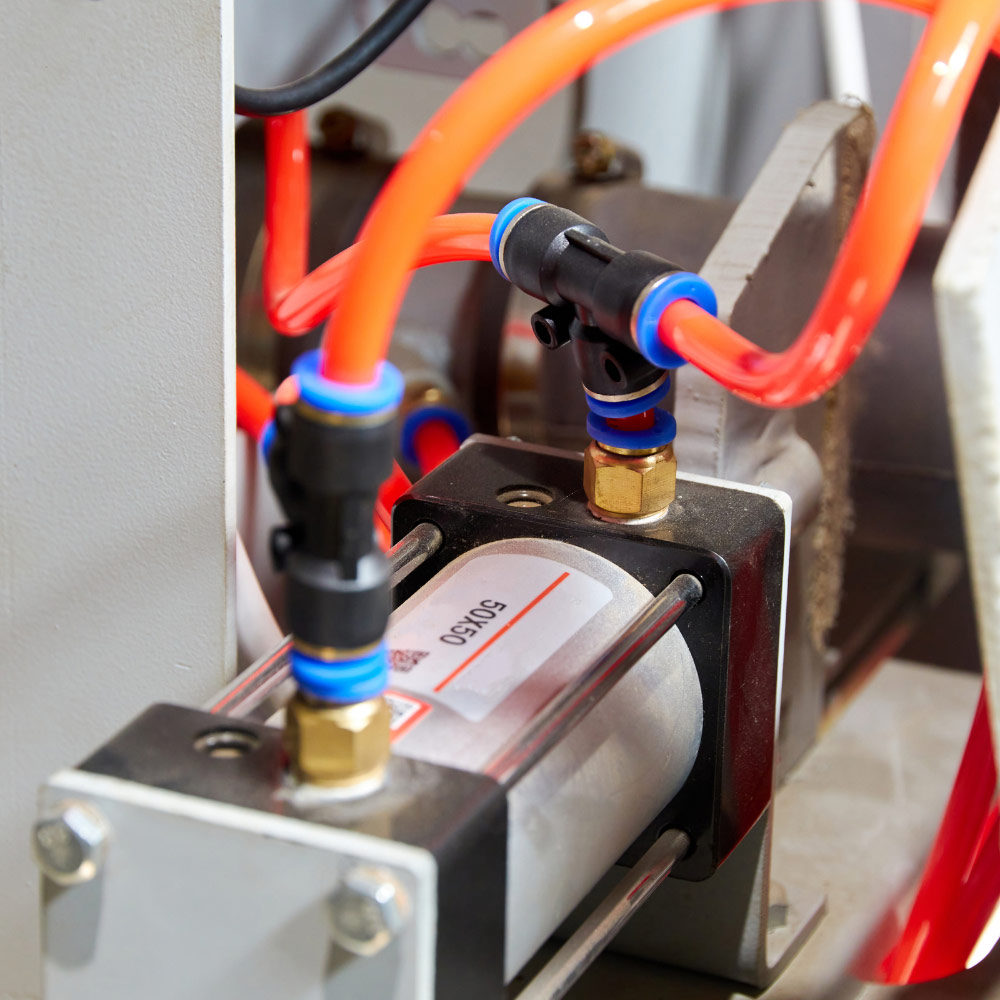

Pneumatic timers use compressed air to operate their mechanisms, making them a core component of pneumatic controls while eliminating electrical sparks and heat. The Ellis/Kuhnke 54 Series, for example, is fully pneumatic and uses a regulated air motor and a gear chain, with an adjustable front knob and an indicator dial that functions as a pneumatic indicator for timing status. The timer provides on-delay or off-delay control via a built-in 4-way valve and automatically resets after the timed cycle. Because it contains no electrical components, it is inherently safe for explosive atmospheres when supplied with clean, non-flammable compressed air.

Other series, such as the PT Series, use a floating spool valve and diaphragm assembly to provide delay and operate over a wide range of control pressures. These designs are suitable for hazardous locations because they make no sparks and do not require explosion-proof housings. However, their performance depends on stable air pressure and contamination-free supply.

Advantages of Pneumatic Timers

- Intrinsic safety: Pneumatic timers are non-electrical and therefore do not introduce ignition sources. The 54 Series uses only mechanical and pneumatic components, making it safe for explosive environments.

- Reliability in harsh conditions: Pneumatic devices tolerate temperature extremes, vibrations, and electromagnetic interference that would damage electronic circuits.

- Simple maintenance: With fewer parts subject to electrical failure, routine maintenance focuses on air quality and mechanical wear.

- Long life: Many pneumatic timers provide millions of cycles of service. The automatic reset feature in the 51 Series and other models extends the unit's life by returning to the start position smoothly.

Limitations of Pneumatic Timers

- Precision and range: Pneumatic timers offer timing ranges typically from fractions of a second up to several minutes. Fine adjustment may be less precise than electronic devices.

- Sensitivity to supply pressure: Fluctuations in compressed air pressure can change the delay. Devices like the PMT Series rely on consistent vacuum signals to start timing.

- Size and mounting: Pneumatic timers may be bulkier than electronic modules and require space for air connections.

Electronic Timers for Hazardous Areas

Electronic timers provide accurate, repeatable delays over a wide range. In hazardous areas, they must employ protective techniques such as intrinsic safety barriers, explosion-proof enclosures, or encapsulation. These measures add cost and complexity. Electronic timers can offer digital displays, multiple functions, and high precision, making them attractive where power is available and safety certifications can be met. However, they may be susceptible to vibration, temperature extremes, and electromagnetic interference. Maintenance is more specialized, involving electrical isolation and periodic certification checks.

Frequently Asked Questions

- Are pneumatic timers safe in explosive atmospheres? Yes. Pneumatic timers use no electrical components, so they do not generate sparks or heat. When supplied with clean, non-flammable compressed air, they meet intrinsic safety requirements for hazardous locations.

- Do electronic timers offer better precision than pneumatic timers? Electronic timers typically provide higher resolution and a wider timing range. However, in hazardous areas, they require explosion-proof enclosures or intrinsic-safety barriers, which add cost and increase maintenance complexity.

- What factors should I consider when selecting a timer for a hazardous area? Evaluate the area’s classification, required timing accuracy, available power, and maintenance expertise. Key considerations are safety requirements, precision needs, and environmental conditions.

- Do I need special certifications for electronic timers in hazardous areas? Yes. Electronic devices must carry appropriate certifications (e.g., ATEX, IECEx, UL) and be installed in accordance with national codes. Consult the manufacturer and relevant standards to ensure compliance before installation.

Decision Framework

To decide between pneumatic and electronic timers in a hazardous area, consider the following.

- Zone classification and safety requirements: If the area is classified as Zone 0/Class I Division 1, fully pneumatic timers may be the simplest compliant solution. Electronic timers require appropriate enclosures and certifications.

- Required timing precision: For basic delays like 0.5–60 seconds, pneumatic models are adequate. If the process needs millisecond accuracy or programmable functions, explosion-proof electronic units may be justified.

- Availability of power: Pneumatic timers run on compressed air. If electrical power is limited or undesirable, they are the default choice.

- Maintenance capabilities: Facilities with pneumatic expertise may prefer mechanical devices. Sites with strong electrical maintenance teams might handle electronic devices more easily.

- Environmental conditions: Extreme temperatures, moisture, or vibration favor pneumatic devices. Stable, controlled environments can support electronic solutions.

Next Steps for Selecting Timers in Hazardous Areas

Choosing between pneumatic and electronic timers in hazardous environments hinges on safety, precision, and practicality. Pneumatic timers provide intrinsic safety and robustness but offer limited timing ranges and require a clean, stable air supply. Electronic timers deliver precision and flexibility but need explosion-proof housings or barriers and careful maintenance. Evaluate your process requirements, hazard classification, and maintenance capabilities to select the best option.

Related Reading

- Ellis/Kuhnke Controls

132 Lewis Street Unit A-2, Eatontown, N.J. 07724

Phone: 1-800-221-0714

Fax: 732-291-8154

Email: Info@ekci.com

- Home Pneumatic Controls Technical Info CAD Drawings Contact Us Pneumatic Timers Blog Site Map