Pneumatic Controls: Reliable Power for Industrial Automation

Compressed air has been quietly powering industry for more than a century. From automated packaging lines to precise positioning systems, pneumatic controls convert the energy of compressed air into smooth, controllable motion. If you’ve ever wondered why so many manufacturers still rely on pneumatics despite the rise of electronics and smart factories, it’s because air-powered controls offer a unique combination of reliability, simplicity, and safety.

What Makes Pneumatic Controls Special?

Ellis Kuhnke Controls has built its reputation on pneumatic devices since 1962. The company manufactures and distributes a complete line of pneumatic control devices, including timers, indicators, counters, valves, cylinders, regulators, and rotary actuators. Unlike electrical systems, pneumatic controls use compressed air as both the power source and the signal medium. This provides several key advantages.

- Inherent safety: Pneumatic systems don’t produce sparks or heat. These features make them ideal for explosive or flammable environments. They comply easily with strict safety standards in food processing, chemical plants, and oil refineries.

- Simplicity and reliability: Requiring minimal moving parts with no electronics, pneumatic controls are robust and easy to maintain. Properly filtered and lubricated air keeps components running for years with minimal downtime.

- Smooth motion control: Air-powered cylinders and actuators deliver precise, cushioned motion without the electromagnetic noise or heat typical of electric motors. This makes them perfect for delicate assembly operations, pick-and-place systems, and material handling.

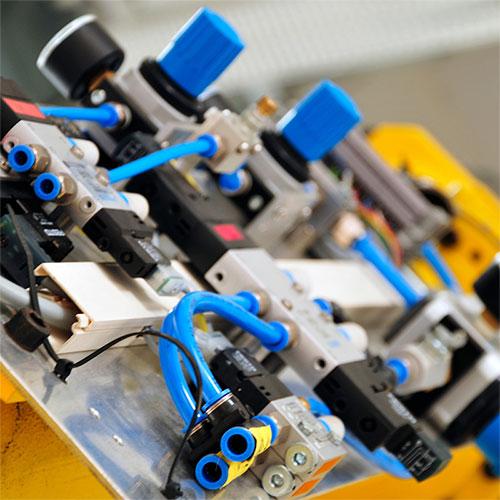

The Building Blocks of Pneumatic Control Systems

A basic pneumatic control system combines several components to create a complete solution.

- Air preparation: Compressors, dryers, and filters clean and condition the air supply to prevent contamination and corrosion.

- Valves: Directional control valves route air to cylinders or other devices. Ellis Kuhnke offers solenoid, mechanical, and pneumatic valves for different control strategies.

- Actuators: Cylinders and rotary actuators convert air pressure into linear or rotational motion. They can be single-acting (spring return) or double-acting (air powers both directions).

- Control elements: Timers, counters, and regulators provide logic and sequencing. For example, a pneumatic timer can delay a signal before a valve actuates, creating a repeatable time-based sequence.

- Feedback devices: Indicators and pressure switches signal positions, pressures, and system status.

Where Pneumatic Controls Excel

Pneumatics are often the preferred choice in applications where electric power is impractical or unsafe. Common uses include the following:

- Packaging and palletizing: Fast cycle times and cushioned motion make air cylinders ideal for moving products without damage.

- Food and pharmaceutical processing: Pneumatic systems meet strict hygiene requirements because they don’t produce electrical sparks or rely on lubricants that could contaminate products.

- Assembly and robotics: Light-weight, compact actuators enable quick, precise movements on assembly lines. Compressed air is readily available in most plants, simplifying installation.

- Material handling: Pneumatic grippers and vacuum cups lift, hold, and release items quickly and safely.

Choosing the Right Components

While pneumatic systems are straightforward, selecting the right components ensures long-term performance. Consider the following:

- Air quality: Clean, dry air is essential. Install filters, dryers, and lubricators to protect sensitive components.

- Load and speed: Match cylinder bore size and valve flow capacity to the forces and cycle times required.

- Control strategy: Decide whether mechanical, solenoid, or air-pilot valves provide the best response time and control logic for your application.

- Environment: Choose materials and seals that withstand temperature extremes, corrosive chemicals, or washdown procedures.

Power Your Process with Confidence

When reliability and safety are non-negotiable, pneumatic controls remain a trusted solution. Ellis Kuhnke Controls’ decades-long expertise in designing and manufacturing timers, indicators, counters, valves, cylinders, and regulators ensures customers receive durable components tailored to their needs. Contact EKCI to discuss your application and discover how pneumatic controls can deliver precise, maintenance-friendly power wherever you need it.

Related Reading

- Ellis/Kuhnke Controls

132 Lewis Street Unit A-2, Eatontown, N.J. 07724

Phone: 1-800-221-0714

Fax: 732-291-8154

Email: Info@ekci.com

- Home Pneumatic Controls Technical Info CAD Drawings Contact Us Pneumatic Timers Blog Site Map