Prolonging Pneumatic Counter Life: Maintenance and Calibration Strategies for Long-Term Reliability

Your lines depend on your pneumatic controls that work. Most failures stem from small issues that accumulate over time. Air that is not clean. Filters that stay in too long. A reset that gets sticky. None of this looks serious on day one, yet it shortens life and creates erratic counts that ripple through production.

The fix is not complicated. Install the counter correctly, keep the air clean and dry, inspect on a real schedule, verify accuracy, and replace wear parts before they fail. That is how you extend service life and avoid surprise stops. The details below show exactly how to do it for the pneumatic counters you buy from EKCI, including panel-mounted totalizers and predetermining models.

What Installation Choices Decide Service Life From Day One?

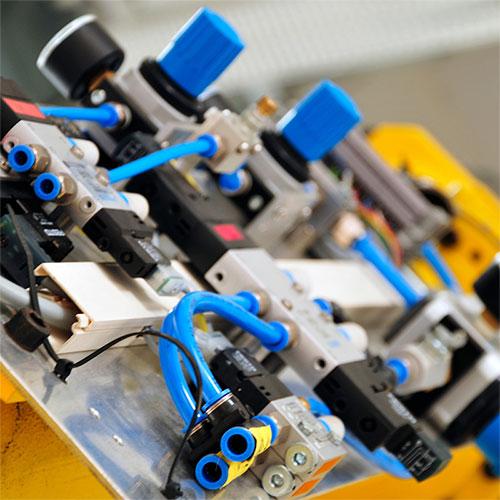

Installation sets the ceiling on reliability. Start with clean, dry, regulated air. Put a filter and regulator upstream. Add a lubricator only if the model and your air system call for it. Mount the counter square to the panel or base so the mechanism does not bind. Use quality fittings and avoid thread tape shreds that can travel into ports and stick inside the counter.

For EKCI panel-mounted totalizers and predetermining counters, respect the model pressure range. Most register impulses in the 30 to 115 psi window. Low-pressure versions run at 7.5 to 30 psi. Keep the supply within that band. Exceeding it increases seal wear and can distort response. Connect the designated pulse input and reset ports with short, clean runs so pulses stay crisp.

- Fit a proper compressed-air filter upstream. Drain bowls before they reach the mark.

- Use only approved pneumatic oil if your system requires lubrication.

- Keep electrical and vibration sources away from the mounting location. Prolonged vibration loosens hardware and can lead to miscounts.

A careful install prevents the early wear that no amount of later maintenance can undo.

How to Set an Inspection Rhythm that Actually Prevents Downtime

A schedule works when it is simple, visible, and linked to the way the counter is used. Tie it to weeks, months, and usage milestones.

- Weekly: Drain moisture from filters. Wipe dust from the face and hardware. Confirm the counter increments during a short test run.

- Monthly: Check all connections for leaks by listening for a hiss at joints and ports. Verify the reset works cleanly every time. Log any sluggish movement or inconsistent counts.

- Six months: Replace or clean the upstream filter element. Remove and clean exhaust silencers if present. Inspect mounting screws for loosening.

- Annually: Pull the counter for a bench check if your environment is dusty or humid. Clean ports, confirm smooth action of the mechanism, and record findings.

Short checks catch problems early. The habit matters as much as the task list.

Air Quality and Lubrication that Protect Seals and Gears

Counters last longest on air that is clean, dry, and stable. Water in the line corrodes metal parts and washes away oil films. Fine dust acts like an abrasive on seals and gears. Keep condensate out by draining filter bowls and any low points in piping. If your plant air varies with seasons, add a dryer or raise maintenance frequency during humid months.

Lubrication depends on your system design. Many counters operate efficiently in clean, dry air. If your line uses a lubricator, feed only a light pneumatic oil at the lowest rate that keeps motion smooth. Too much oil attracts dust and can gum up small mechanisms. Never use heavy greases or products with solid additives on internal parts. If you are unsure, ask EKCI for the correct oil type for your setup.

Clean, dry air and correct lubrication slow seal wear and keep digit wheels and valves moving freely.

Calibration that Keeps Pneumatic Counters Honest

Accuracy drifts when mechanisms wear, when screws loosen, or when pulses get too short. A quick, controlled check keeps you ahead of errors.

Set up a safe test. Isolate the counter from the live process. Apply a known series of pneumatic pulses and compare the display to the expected totals. For predetermining counters, set a number and confirm the output trips exactly on that count. Record the results and the conditions you used.

EKCI usage notes that matter during checks:

- Most models need a minimum pulse duration of 8 ms with a 10 ms pause between pulses. Very short pulses can be missed.

- Manual or pneumatic resets require a reset signal of about 180 ms to clear the count fully.

- Predetermining units include an internal three-way valve. Confirm the supply and output ports are on the correct lines before testing the trip point.

If the counter misses pulses at speed, clean the ports and mechanism, then retest at the proper pressure. If miscounts persist, plan a service or replacement. A written log of dates, methods, and results turns calibration into a reliable guardrail rather than a guess.

Replace Wear Parts Before They Fail

Seals, springs, and small valve elements are consumables in harsh environments. Replace them at the first signs of trouble rather than after a shutdown. Watch for air leaks at the body, a reset that feels gritty, digits that advance slowly, or a unit that needs higher pressure to respond. If two or more symptoms appear together, a full overhaul or replacement is usually the better choice.

Use original parts. Mixing materials can change clearances and shorten life. Keep a small stock of the wear items that match your installed base. If your counters track cycles, use that data to schedule service at a cycle count that suits your environment. That turns the counter into a maintenance trigger rather than only a totalizer.

Timely part swaps cost less than emergency calls and lost production.

EKCI Model-Specific Pneumatic Controls to Checks to Add to Your Routine

These points align with the counters we supply and support. Add them to your bench cards.

- Panel-mounted totalizers: Confirm impulse pressure sits within the model range during normal runs. Verify the reset button and the pneumatic reset both clear the display to zero on the first try.

- Predetermining counters: After setting the lower scale, run a short test to confirm the built-in valve trips at the right count and stays latched until reset. Check that the supply and output ports to the valve are clean and free of restriction.

- Low-pressure models: If you run at 7.5 to 30 psi, be strict with air cleanliness. Lower pressure margins leave less room for clogged media and sticky motion.

These small, focused checks connect the general rules to the hardware on your line.

A Short Path to Longer Service Life for Pneumatic Controls

Good installation, clean air, simple inspections, honest calibration, and planned part replacement keep pneumatic counters reliable for years. If you want a maintenance card and calibration routine matched to your model and line speed, we can help. Reach out to EKCI for service guidance, parts, or a quick review of your setup so your counters keep counting and your line keeps moving.

Related Reading

- Ellis/Kuhnke Controls

132 Lewis Street Unit A-2, Eatontown, N.J. 07724

Phone: 1-800-221-0714

Fax: 732-291-8154

Email: Info@ekci.com

- Home Pneumatic Controls Technical Info CAD Drawings Contact Us Pneumatic Timers Blog Site Map