Do Pneumatic Timers Ensure Precise Dosage Control in Pharma Production?

In pharmaceutical manufacturing, precision isn't merely desirable; it's a strict regulatory mandate. For professionals overseeing processes such as aseptic filling, sterile packaging, and exact chemical dosing, even minor timing discrepancies can lead to costly recalls, regulatory fines, and potential risks to patient safety. Regulatory bodies like the FDA rigorously enforce standards to ensure product consistency, accuracy, and safety. Amid these pressures, the role of pneumatic timers within pharmaceutical process controls has emerged as a critical solution. But does pneumatic timing technology genuinely provide the precision and repeatability the pharmaceutical industry demands?

Regulatory Precision: Why Timing Accuracy Matters

FDA regulations, particularly CFR 21 Part 211 (Good Manufacturing Practice, or GMP), explicitly mandate consistent, verifiable accuracy in pharmaceutical production processes. Timed processes like sterilization cycles, dosage controls, and filling operations must consistently meet predetermined specifications, with minimal deviation. An error of just a fraction of a second during drug filling can significantly impact dosage accuracy, potentially triggering regulatory audits or product recalls.

A well-known FDA compliance audit highlighted a facility that initially relied on electronic timers to control its aseptic filling machines. Despite extensive maintenance, their equipment displayed inconsistent timing, leading to dose variability. After careful review, the FDA inspectors explicitly recommended implementing more reliable timing solutions, highlighting the regulatory demand for repeatable, accurate control.

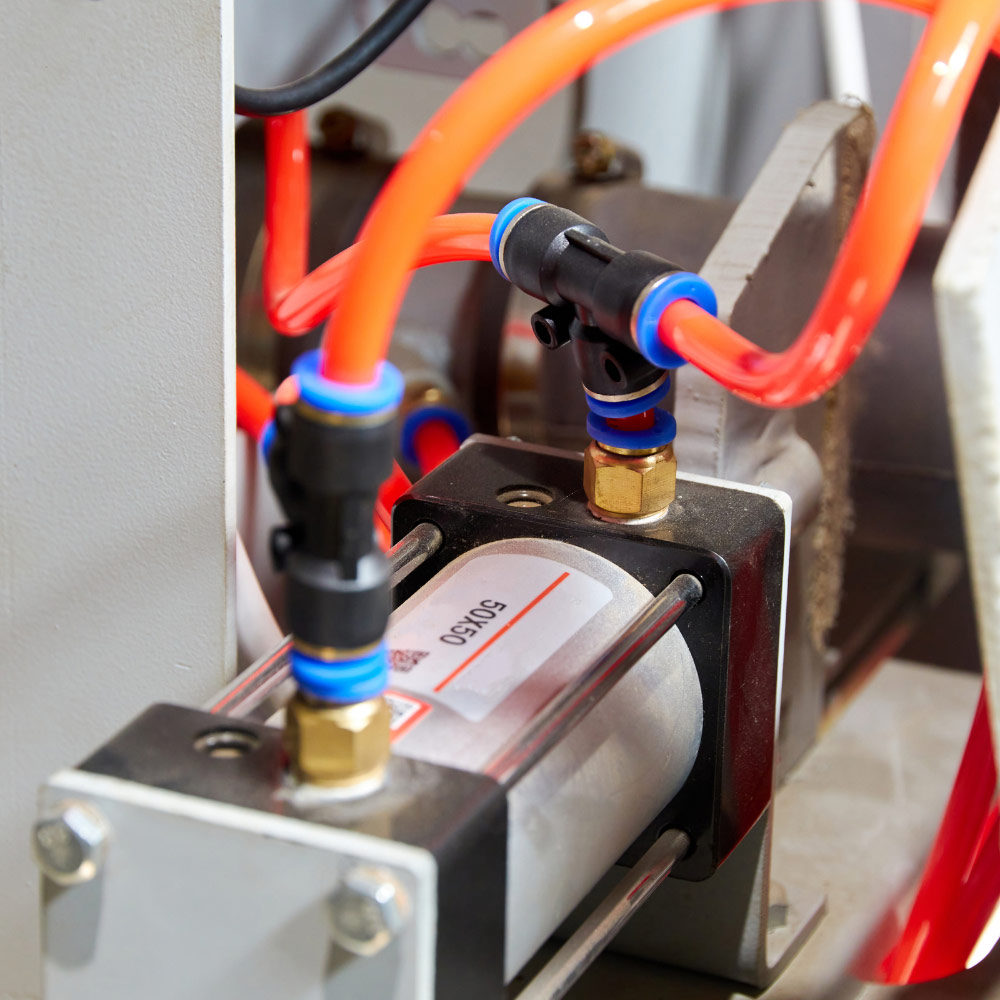

Pneumatic Timers: Stability Without the Drift

Pharmaceutical production managers have increasingly turned to pneumatic timers because these devices inherently eliminate problems associated with electronic timing drift. Unlike electrical timers, pneumatic timers do not suffer from electronic component wear or voltage inconsistencies, two familiar sources of timing deviations.

In a specific pharmaceutical filling line case study, an electronic timing system was consistently drifting over production shifts due to slight voltage fluctuations. The result was an unacceptable variance in dosage accuracy. After retrofitting the line with pneumatic controls—using compressed air-driven timers to actuate filling valves—technicians measured immediate improvement. Pneumatic timers delivered consistent intervals throughout every shift, entirely independent of electrical supply fluctuations. Dosage accuracy stabilized immediately, restoring regulatory compliance and significantly reducing costly product waste.

Enhancing Sterile Process Reliability

In aseptic pharmaceutical environments, maintaining sterile conditions and preventing contamination is paramount. Pneumatic timers contribute significantly to sterile process reliability precisely because of their purely mechanical, sealed designs. Without electrical wiring or complex circuits that may degrade or require intrusive maintenance, pneumatic timing controls eliminate contamination entry points associated with electronic systems.

For example, one sterile manufacturing facility previously experienced frequent contamination alerts traced back to repeated servicing of electrical timing equipment inside cleanrooms. Switching to pneumatically timed valve actuation for sterilization cycles entirely removed this contamination pathway. Pneumatic timers required minimal routine maintenance, significantly lowering contamination risks and boosting the overall reliability and cleanliness of the production process.

Validated Repeatability in High-Volume Production

High-volume pharmaceutical production demands unerring repeatability. Pneumatic timers rely on mechanical diaphragms or precision pistons to deliver exact timing intervals, repeatable to within fractions of a second across countless operational cycles.

During validation tests at a prominent vaccine production facility, pneumatic timers were rigorously evaluated for cycle-to-cycle consistency. The results were compelling: pneumatic timers delivered repeatable valve actuations within tightly controlled tolerances, consistently surpassing the strict validation criteria required under FDA GMP protocols. This documented repeatability directly translated into higher product yields, fewer production halts, and far easier regulatory compliance audits.

Streamlined Compliance: Pneumatic Timers and GMP Audits

Pharmaceutical facilities undergo regular and intense FDA inspections. Every aspect of production timing is scrutinized—from dosing accuracy to sterilization cycles. Pneumatic timing solutions simplify these audits. Their purely mechanical function provides auditors with straightforward, easily verifiable performance data, reducing audit complexity.

At one central pharmaceutical plant, transitioning to pneumatic timing dramatically improved audit outcomes. Prior audit cycles repeatedly flagged inconsistencies in electronic timing systems, generating lengthy investigations. Once pneumatic timers replaced electronic devices, inspection durations decreased substantially, with FDA auditors quickly verifying timer consistency and reliability. This streamlined process improved the facility's compliance reputation, reduced audit-related stress, and saved substantial administrative costs.

Operational Simplicity, Reduced Downtime

Beyond regulatory and accuracy advantages, pneumatic timers deliver direct operational benefits in pharmaceutical manufacturing. Their robust, mechanical construction withstands demanding cleanroom conditions, eliminating many routine maintenance procedures standard to electronic timers. This leads directly to reduced downtime, higher line productivity, and significantly lower overall operating costs.

For instance, a tablet coating line previously reliant on electronic timing frequently halted operations for timer recalibration and maintenance. After implementing pneumatic timers to control coating intervals precisely, downtime incidents declined dramatically. Production output increased measurably, operational expenses dropped, and staff reported noticeably lower maintenance burdens, all attributable directly to pneumatic timer adoption.

Investing in Precision: Pneumatic Timers as Strategic Assets

Ultimately, pneumatic timers represent far more than process control components; they are strategic investments in pharmaceutical quality, regulatory compliance, and operational efficiency. Facilities that adopt pneumatic timers for dosage and process control consistently experience fewer regulatory violations, fewer product recalls, and dramatically reduced downtime. In practical terms, pneumatic timers ensure that pharmaceutical products reaching patients reliably meet exact standards of safety and effectiveness.

In a heavily regulated industry where accuracy and repeatability directly impact patient safety and operational profitability, pneumatic timers deliver demonstrable, proven value. They ensure that every process step—from filling to sterilization—is precise, repeatable, and fully compliant. Far from simply another timing option, pneumatic timers emerge as indispensable tools for pharmaceutical professionals who value uncompromising accuracy, safety, and regulatory certainty.

When your operation demands precision, pneumatic controls aren't just a logical choice; they're the essential decision ensuring pharmaceutical excellence, regulatory compliance, and patient safety every single day.

Related Reading

- Ellis/Kuhnke Controls

132 Lewis Street Unit A-2, Eatontown, N.J. 07724

Phone: 1-800-221-0714

Fax: 732-291-8154

Email: Info@ekci.com

- Home Pneumatic Controls Technical Info CAD Drawings Contact Us Pneumatic Timers Blog Site Map