Simplifying Safety: Why Pneumatic Controls Excel in Explosive Industrial Environments

In chemical plants, oil refineries, and grain silos, sparks from electrical controls pose severe explosion risks. Despite the widespread use of electrical systems, the hidden dangers associated with their operation in hazardous locations necessitate serious reconsideration. Electrical controls, which seem reliable and modern, can inadvertently generate sparks capable of igniting volatile substances and causing catastrophic explosions. Choosing the right control systems in such environments is not merely a preference but a critical safety decision. Pneumatic control systems offer an ideal solution because they eliminate ignition sources entirely, require simpler maintenance routines, and provide unmatched reliability, ensuring safer and uninterrupted operations.

How Pneumatic Controls Eliminate Spark Risks

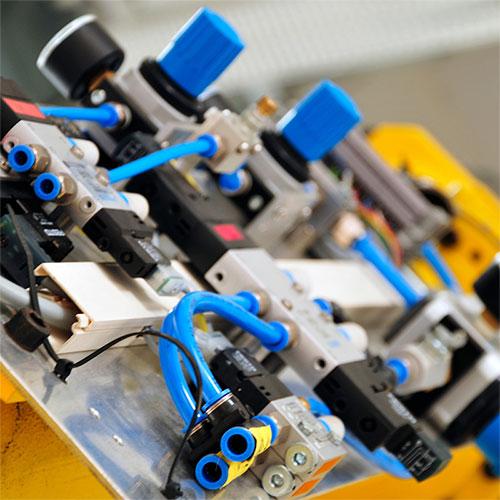

Pneumatic controls rely exclusively on compressed air, entirely removing the reliance on electricity. This fundamental design choice effectively eliminates any possibility of spark generation. Unlike electrical actuators and relays, pneumatic actuators and valves operate without generating electrical charges, significantly reducing the risks associated with sparks in volatile environments. Additionally, pneumatic systems typically incorporate non-sparking materials such as brass, aluminum, and specialized plastics. These materials are selected specifically for their resistance to friction and impact-induced sparks, further reinforcing their safety profile in hazardous locations.

The operational principle behind pneumatic controls is straightforward yet highly effective. Compressed air is channeled through valves and actuators to produce mechanical motion. This design eliminates complex electrical circuitry and reduces potential points of failure, making pneumatic systems exceptionally reliable. This inherent simplicity ensures a safer operational environment, providing peace of mind in industries where even minor sparks can trigger major disasters.

When to Prioritize Pneumatic Controls

Understanding precisely when pneumatic solutions provide superior safety benefits clarifies their essential role in hazardous environments. Certain high-risk scenarios inherently favor pneumatic controls due to their unique attributes.

- Explosive Vapors or Gases: Facilities handling volatile substances, such as petrochemical plants, greatly benefit from the intrinsic safety of pneumatic systems. Pneumatic controls inherently eliminate potential ignition sources, dramatically reducing explosion risks.

- Reactive Chemical Processes: Operations involving highly reactive chemicals or unstable substances require reliable, fail-safe control mechanisms. Pneumatic systems' inherent safety and consistent performance make them indispensable in these scenarios.

Recognizing and clearly defining these situations provides strong justification for prioritizing pneumatic controls, underscoring their critical role in maintaining operational safety in hazardous industrial settings.

Ease of Maintenance and Reliability

Beyond their safety benefits, pneumatic controls offer significant advantages related to ease of maintenance and reliability. The simplified mechanical structure of pneumatic systems inherently reduces the complexity of maintenance tasks and improves system longevity.

- Easy Diagnostics: Identifying and rectifying faults in pneumatic systems is typically straightforward, owing to their mechanical simplicity. Pneumatic faults are usually mechanical rather than electrical, making them easier and quicker to diagnose and repair.

- Minimal Downtime: Pneumatic systems involve fewer components and simpler structures, significantly reducing the frequency and complexity of maintenance. Less frequent maintenance results in minimized downtime, ensuring continuous operations and enhanced overall reliability.

These maintenance advantages directly complement the safety and operational benefits of pneumatic controls, providing comprehensive reasons for their implementation.

Choose Safety, Choose Pneumatic Controls

Ultimately, pneumatic control systems offer the best solution for ensuring safety, reliability, and ease of maintenance in hazardous environments. By completely eliminating potential ignition sources and streamlining maintenance procedures, pneumatic controls provide a compelling argument for their adoption. Prioritizing these systems helps ensure continuous, safe operations, protecting both personnel and critical processes from catastrophic incidents. Make the informed and proactive decision today to implement pneumatic controls in your industrial operations, significantly enhancing operational safety and reliability.

Related Reading

- Ellis/Kuhnke Controls

132 Lewis Street Unit A-2, Eatontown, N.J. 07724

Phone: 1-800-221-0714

Fax: 732-291-8154

Email: Info@ekci.com

- Home Pneumatic Controls Technical Info CAD Drawings Contact Us Pneumatic Timers Blog Site Map