Pneumatic Indicators: How to Choose the Right Visual Pressure Indicator for Your Application?

When designing or managing pneumatic systems, clearly and reliably indicating system pressure is essential. Operators and maintenance teams rely on visual indicators to quickly assess whether a system is pressurized, at rest, or requires immediate attention. Selecting the correct pneumatic indicator type has a direct impact on operational safety, efficiency, and troubleshooting speed.

One of the critical decisions engineers face is determining the best type of pneumatic indicator to integrate into their specific applications. Visual indicators range significantly in complexity, mounting options, color indications, and operational features. Common choices include Panel-Mounted Visual Indicators, Two-Color Indicators with Detent Modes, Port-Mounted Indicators, and specialized Visual Pressure Indicators. At Ellis/Kuhnke Controls, can help answer the critical question: "What factors should I consider when choosing between different pneumatic indicator types for my project?"

Understanding Your Options: Types of Pneumatic Indicators

Panel Mounted Pneumatic Indicators

Panel mounted pneumatic indicators provide simple and clear visual confirmation of the presence of air pressure. Typically designed for installation in control panels, these indicators use a single color that visibly appears or changes once system pressure reaches a preset level.

- Ideal For: Clear, straightforward indication in instrument panels, control panels, or operator consoles.

- Typical Pressure Range: Generally operates effectively within a range of 20 to 115 psi.

- Mounting and Visibility: Easy panel mounting with spring locking or screw fastening, and clear visibility from various angles.

These indicators are simple, robust, and cost-effective, making them a common choice for basic installations that require reliable visual confirmation without advanced functionality.

Two-Color Pneumatic Indicators (NF Series & AL Series)

Two-color visual pneumatic indicators, such as the NF and AL series, provide intuitive status indication by clearly changing color according to the presence or absence of pressure. This design significantly enhances readability, providing instant recognition of system status.

- Two Modes of Operation (NF Series)

- Spring Return Mode: The indicator automatically returns to its initial color once the pressure drops.

- Detent Mode: The indicator remains in its switched color until a second pneumatic signal resets it, allowing for a stable indication of event occurrence or system status.

- Enhanced Visibility (AL Series): Offers a rounded lens with a 180° viewing angle, allowing operators to quickly determine system status from any angle.

- Flexible Mounting: Designed for oil-tight panel mounting, providing reliability and convenience in environments with potential oil or moisture exposure.

- Typical Pressure Range: Operates reliably between 20 and 150 psi, depending on the selected mode (detent or spring mode).

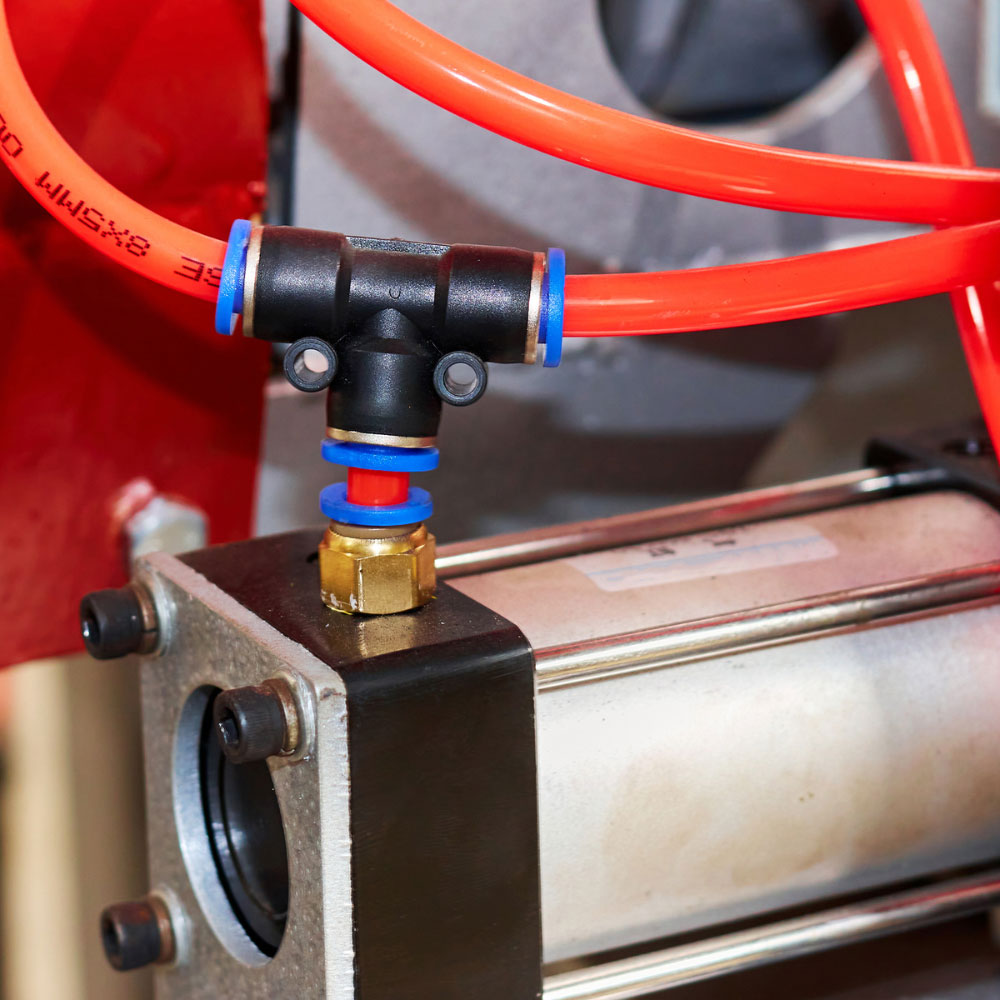

Port Mounted Pneumatic Indicators

Port mounted indicators attach directly into pneumatic system ports, making them invaluable for diagnostic, testing, or troubleshooting functions. They offer direct visual confirmation of pressure at strategic system points.

- Minimal Footprint: Compact construction from brass hex stock allows installation even in confined spaces.

- Ease of Integration: Simple screw-in attachment into existing pneumatic ports with standard threads.

- Immediate Diagnostics: Visual indicator "pop-up" functionality clearly signals the presence of pressure, enabling quick diagnostic checks without specialized equipment.

- Pressure Range: Typically effective in a higher pressure range from approximately 45 to 145 psi.

These indicators serve as robust, low-cost diagnostic tools, significantly aiding maintenance teams in quickly identifying operational status directly at the pneumatic line.

Key Questions to Consider When Selecting Pneumatic Indicators

- What Visibility Do You Require? Consider how quickly and clearly operators must understand the system's status. If immediate readability at a glance is critical, two-color indicators with broad viewing angles (like the AL series) offer substantial operational benefits.

- Do You Require Stable or Momentary Status Indication? Decide whether you need a continuous indication that persists until intentionally reset, or an indicator that automatically returns to a baseline state. Indicators offering detent mode (NF Series) maintain their switched state, ideal for signaling events that operators should not overlook.

- How Constrained is Your Installation Space? Space constraints significantly affect the type of pneumatic indicator you choose. Port-mounted indicators offer compact installation directly on pneumatic lines without additional panel modifications. For tight panels or restricted spaces, compact panel-mounted indicators with minimal mounting depth provide easy integration.

- What Environmental Conditions Will the Indicator Face? Evaluate the robustness required to withstand exposure to harsh environments, including moisture, vibration, oils, and temperature fluctuations. Oil-tight and corrosion-resistant indicators (such as AL and NF Series) are necessary for harsh operational conditions to ensure reliability and maintain consistent visibility.

- What Pressure Range Will Your Application Operate Within? Ensure the chosen pneumatic indicator aligns perfectly with your system's operational pressure range. Indicators clearly specify their optimal operating pressures—select indicators that comfortably cover your system's maximum and minimum pressures for reliable and consistent performance.

Making an Informed Decision for Your Business

When making your choice, follow these simple but essential steps.

- Assess Application Requirements: Clearly define your operational parameters, including visibility needs, environmental exposure, available space, and the required pressure range.

- Review Manufacturer Specifications: Thoroughly check indicator specifications, including operating pressure ranges, environmental ratings, and physical dimensions.

- Evaluate Installation Simplicity: Consider ease of installation, accessibility, and ease of replacement or maintenance.

- Plan for Long-term Reliability: Prioritize robust, durable indicators suited to your operational environment to minimize downtime and reduce long-term costs.

Tips for Choosing the Right Pneumatic Indicator

Selecting the correct pneumatic indicator for your application involves more than simply choosing a convenient option from a catalog. Careful consideration of visibility needs, operational environment, space constraints, pressure range, and functionality ensures your pneumatic system remains reliable, effective, and operator-friendly.

Taking the time to carefully evaluate each indicator type and align it with your specific application will greatly enhance operational effectiveness, simplify troubleshooting, and support reliability across your pneumatic systems.

If you're ready to enhance visibility, improve reliability, and optimize your pneumatic system, contact Ellis/Kuhnke Controls. Our expert team can help you in selecting and implementing the most effective pneumatic indicators to meet your exact needs.

Related Reading

- Ellis/Kuhnke Controls

132 Lewis Street Unit A-2, Eatontown, N.J. 07724

Phone: 1-800-221-0714

Fax: 732-291-8154

Email: Info@ekci.com

- Home Pneumatic Controls Technical Info CAD Drawings Contact Us Pneumatic Timers Blog Site Map