New Kuhnke Pneumatic Cylinders: How to Choose the Right Standard for Your Machine

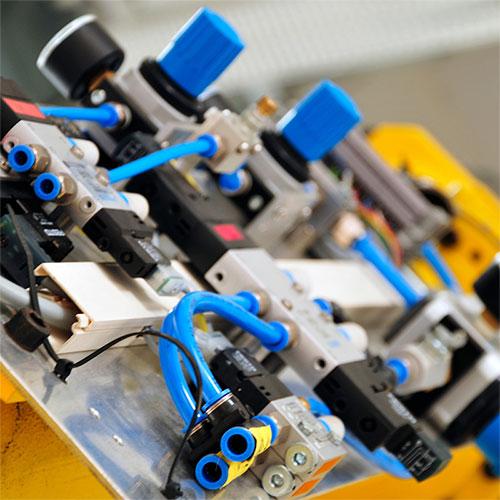

Getting the Right Pneumatic Control Systems for Your Operation

If you are buying pneumatic cylinders for real production equipment, you are not shopping for a “cylinder,” you are shopping for a mechanical interface standard, a force envelope, a duty cycle expectation, and a maintenance reality. The right choice comes down to three questions: What standard does your machine need? What bore and stroke does your application demand? What environment will punish the cylinder over time?

- For most new industrial builds, ISO 15552 is the default.

- For tight, high-cycle spaces, ISO 6432 is the right tool.

- For legacy CNOMO footprints, CNOMO is non-negotiable.

At EKCI, we stock and support Kuhnke pneumatic cylinders specifically because they are built for interchangeability and long-term industrial reliability, not hobby use, not one-off prototypes.

What These Standards Really Mean To a Buyer

ISO 6432 (Micro round cylinders)

ISO 6432 is about compactness and repeatable motion in small spaces. It is the standard you reach for when the cylinder has to disappear into the machine. It is common in high-throughput automation where stroke lengths are modest, tooling is light, and speed matters.

These cylinders are not where you go for heavy loads, long strokes, or aggressive deceleration. They are built to be small, fast, and efficient for their class.

ISO 15552 (Industrial profile and tie-rod cylinders)

ISO 15552 is the default standard for general industrial automation because it balances force, stroke flexibility, mounting ecosystem, and serviceability. It is the standard most plants aim for when standardizing spares, simplifying maintenance, and designing new stations.

ISO 15552 gives you the most straightforward interchangeability for new builds and upgrades. It is also where you see the most mature options for cushioning, sensing, and mounting flexibility.

CNOMO (Legacy industrial standard)

CNOMO cylinders exist because many pieces of serious equipment were built around CNOMO footprints. The standard is still relevant because maintenance reality is relevant. If a machine has CNOMO mounts, swapping to ISO typically means mechanical changes, downtime, and risk.

If your equipment is CNOMO, you buy CNOMO to keep production moving.

Pneumatic Controllers: Side-By-Side Comparison Table of Pneumatic Cylinders

|

What you care about |

ODM Series |

HDM Series |

CNDM Series |

|

Primary standard |

ISO 6432 |

ISO 15552 |

CNOMO |

|

Bore range |

8 to 25 mm |

32 to 125 mm |

32 to 200 mm |

|

Typical role |

Compact automation |

General industrial workhorse |

CNOMO footprint replacement |

|

Pressure rating class |

Up to 10 bar class |

Up to 10 bar class |

Up to 10 bar class |

|

Cushioning |

Typically none or limited |

Adjustable cushioning options |

Adjustable cushioning options |

|

Sensor integration |

Magnetic and non-magnetic options |

Magnetic and non-magnetic options |

Magnetic and non-magnetic options |

|

Best fit for new designs |

Sometimes |

Yes |

Only if required |

|

Best fit for legacy replacements |

Yes, if ISO 6432 |

Yes, if ISO 15552 |

Yes, if CNOMO |

Engineering Selection: The Four Checks That Prevent Wrong Orders

1) Standard and mounting interface

Start here, not with bore size. If the machine is built to ISO 15552 or CNOMO, the wrong standard is not a “maybe,” it is a mechanical mismatch. Confirm the existing cylinder’s standard and mount style first, then select the matching Kuhnke series.

- Replacing a compact cylinder buried inside a pick-and-place head with ISO 6432 mounts is the direct route for ODM.

- Replacing a cylinder on a packaging line with common industrial mounts, ISO 15552, and HDM usually wins.

- Replacing cylinders on older European equipment with CNOMO footprints, CNDM is the shortest path to a true drop-in.

2) Force, bore, and real pressure

You already know the math. The mistake buyers make is assuming “6 bar” behaves like a constant. In production, pressure at the cylinder can drop from line losses, undersized valves, restrictive fittings, or long hose runs.

If the cylinder is borderline on force at your nominal pressure, it will become a problem during real throughput, not during bench testing. If you are close, size up the bore or tighten up the pneumatic circuit.

3) Stroke length and stability

Long strokes introduce rod buckling risk, guide wear, and alignment sensitivity. If your stroke is long relative to the bore, the cylinder can still be the right choice, but the mechanical design must account for the realities of side load and guiding.

- If the load has side forces, use proper external guidance. Do not ask the cylinder to be a linear guide.

- Consider anti-rotation options when tooling cannot twist, or when a rod-end load can induce rotation.

- Use cushioning when mass and speed will slam the piston into end caps.

4) Environment, seals, and rod material

This is where “it works” becomes “it lasts.”

Use stainless rods when:

- Washdown, humidity, salt air, or chemical exposure is part of the plant environment.

- Corrosion on rods would damage seals and create repeat failures.

Use high-temperature seal options when:

- Ambient temperature is elevated, or radiant heat exposure is likely.

- Your media, cleaners, or process conditions punish standard elastomers.

Where Each Series Wins, By Environment and Machine Type

ODM Series, where it is the right tool

- Tight automation stations where cylinder envelope is the limiting factor

- High-cycle light-duty tasks like stops, ejectors, small clamps, indexing mechanisms

- Compact assemblies where sensor feedback is still required

It delivers ISO 6432 interchangeability in a compact package. You get clean integration without redesigning the machine around a larger actuator.

HDM Series, where it pays for itself

- Packaging and material handling where forces are moderate to high

- Production lines where cushioning and repeatability protect equipment from shock

- Plants that want a standard cylinder family for spares and maintenance

ISO 15552 is the practical standard for most new and upgraded industrial equipment, and it supports the broadest mounting and configuration ecosystem.

CNDM Series, where it prevents downtime

- Legacy CNOMO-based machines, where the mounts are fixed and proven

- European-origin equipment still running critical production

- Retrofit projects where mechanical changes are expensive or risky

It keeps the footprint consistent. Your team replaces the cylinder, not the machine design.

Common Buying Mistakes, And How to Avoid Them

- Choosing by bore only: If the standard does not match the machine, the bore size does not matter. Confirm the standard first.

- Ignoring deceleration and end-of-stroke energy: If the load is heavy and speed is high, cushioning is not a nice-to-have. It is how you protect the cylinder, the mounts, and the machine frame.

- Assuming the cylinder can take side load: A pneumatic cylinder is an actuator, not a guide. If there is side load, design external guidance.

- Under-specifying rod corrosion resistance: Rod corrosion destroys seals and drives recurring failures. If the environment is harsh, specify stainless rod options and the right seal configuration.

EKCI Recommendation: How to Narrow Your Choice Quickly

- Confirm the standard on the existing machine: ISO 6432, ISO 15552, or CNOMO.

- Confirm bore and stroke from the existing cylinder or machine spec.

- Confirm sensing and cushioning needs based on speed, mass, and control logic.

- Confirm the environment and choose the rod and seal options that will survive your plant.

If you share your current cylinder’s standard, bore, stroke, mount style, and whether you need magnetic sensing, we can help you select the correct Kuhnke configuration without guesswork.

Related Reading

- Mounting Pneumatic Timers with Pneumatic Indicators: Comparing Panel, Subplate, and Manifold Installations

- Fixing Inaccurate Delays in Pneumatic Timers: Practical Troubleshooting Guide

- Rotor-Stop Pneumatic Timers: Precision Control for Critical Processes

- Pneumatic Timers: How They Work and How to Choose the Right Model

- Ellis/Kuhnke Controls

132 Lewis Street Unit A-2, Eatontown, N.J. 07724

Phone: 1-800-221-0714

Fax: 732-291-8154

Email: Info@ekci.com

- Home Pneumatic Controls Technical Info CAD Drawings Contact Us Pneumatic Timers Blog Site Map