Basic Principles of Pneumatic Control Systems

Pneumatic control systems are considered a branch of engineering that uses pressurized air or gas to control and create movement. For the engineering world, pneumatic systems are effective and economical.

How do these systems work?

A pneumatic control system uses compressed air that is carried through plastic and copper tubes—from a controller to a control device. Controlling systems with this method operate with the help of sensors and thermostats that can bleed or retain line pressure from the sensor to the actuator. Each sensor that is used must be responsive to changes in static pressure, temperature, and humidity. The sensors provide clear feedback in controls that open and close actuators to meet specific control set points.

Actuators are built with diaphragms and springs that function in designated sequences with control signals. Systems will use compressed air as the primary communication method.

Common reasons people turn to pneumatics is because of:

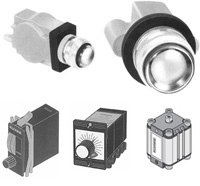

Modular control components: the brain of the control system is distributed throughout the system using many pneumatic building blocks, such as thermostats and pneumatic valves. With pneumatic controls, almost any control strategy is possible.

Actuators: pneumatic actuators, also known as air-powered motors that are designed to control valves and dampers. Of all the actuators types available, pneumatic variants are the most durable, reliable, and economical. They do not need much maintenance outside of inspection and minor adjustments.

Pneumatic Controls:

Our team is standing by to answer all your questions about pneumatic systems. You should reach out to us today!

Related Reading:

- Pneumatics and Robots

Pneumatic systems are being used in the creation of different types of robot. There are several reasons, such as safety, efficiency, and ease, as to why pneumatic systems are utilized in the robotics industry. - Pneumatics and Hydraulics

- Long Delay Timers

- Ellis/Kuhnke Controls

132 Lewis Street Unit A-2, Eatontown, N.J. 07724

Phone: 1-800-221-0714

Fax: 732-291-8154

Email: Info@ekci.com

- Home Pneumatic Controls Technical Info CAD Drawings Contact Us Pneumatic Timers Blog Site Map