Understanding Pneumatic Valves and Actuators

Pneumatics are valuable tools used in various industries. These pressurized systems need several safety measures. One of these measures is pneumatic valves. Actuators are parts of a machine or device that helps it achieve movement by converting energy. Many types of pneumatic valves are based on actuators. If you use pneumatics in your business, it’s important to understand pneumatic valves and actuators.

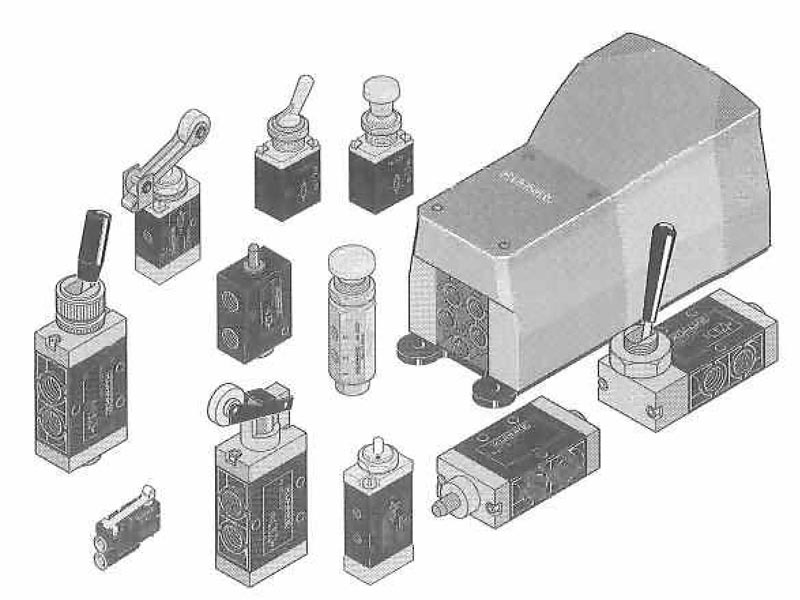

Pneumatic valves are equipped with three types of actuators: mechanical, electromagnetic, and air-operated. Let’s go over the type of pneumatic valves based on their actuators.

Pneumatic valves are equipped with three types of actuators: mechanical, electromagnetic, and air-operated. Let’s go over the type of pneumatic valves based on their actuators.

- Mechanical Valves – Also known as hand-operated, these valves use manual power. They are used when using electricity is dangerous and are used for air or liquid flow. You use your hand or feet to apply energy with a push-pull motion or simply pressing a button. Some mechanical valves work with the power of friction or lever arms.

- Solenoid Valves – These valves control liquid in a hydraulic system and airflow in a pneumatic one. Solenoid valves work best in industrial operations because they require a consistent temperature. Other applications of these valves are dishwashers and irrigation systems. Solenoid valves open and close in reply to an electric signal.

- Air Operated Valves – The design of these valves is similar to solenoid valves. However, they reply to air pressure instead of responding to an electric signal. If you wish to use your valve remotely and without electricity, they are a good choice. Air-operated valves are commonly found in fertilizing manufacturing facilities and chemical factories.

Related Reading about Pneumatic Valves

- Ellis/Kuhnke Controls

132 Lewis Street Unit A-2, Eatontown, N.J. 07724

Phone: 1-800-221-0714

Fax: 732-291-8154

Email: Info@ekci.com

- Home Pneumatic Controls Technical Info CAD Drawings Contact Us Pneumatic Timers Blog Site Map

If you are looking for Pneumatic Controls, Pneumatic Valves then look no further than Ellis/Kuhnke Controls.