How Can I Implement a Two-Hand Control Pneumatic Circuit for Improved Operator Safety?

Nothing causes more concern than a machine operator who can accidentally start high-force equipment at the wrong moment. Whether you run a small press or a larger assembly line, the potential for injury—if hands or limbs aren’t clear—can be immense. Many facilities fear the worst when they hear about unintended cylinder activations causing harm or triggering an emergency shutdown.

Nothing causes more concern than a machine operator who can accidentally start high-force equipment at the wrong moment. Whether you run a small press or a larger assembly line, the potential for injury—if hands or limbs aren’t clear—can be immense. Many facilities fear the worst when they hear about unintended cylinder activations causing harm or triggering an emergency shutdown.

A well-implemented two-hand pneumatic control circuit addresses these worries by requiring simultaneous button presses before a cylinder can move. The circuit vents pilot air and halts motion if either hand is removed. Two-hand logic is effective and can seamlessly integrate with your machine’s pneumatic design.

Why Two-Hand Control is a Game-Changer for Safety

Before jumping into circuit diagrams, it’s essential to understand the rationale behind two-hand control. Accidents in pneumatic systems often happen not because the equipment fails but because the operator inadvertently triggers motion while their hands are in a dangerous position.

Two-hand control physically forces the operator to keep both hands on separate actuators—usually pushbuttons or valves—until the machine stroke is complete. This design is popular in presses, cutting equipment, and any scenario where a single stray hand movement can lead to serious injury. With both hands engaged, the operator can’t accidentally place a hand under a descending ram or in the path of a moving cylinder rod.

- Prevents One-Handed Activations: A single button, switch, or lever becomes insufficient to start the cycle, drastically reducing human error.

- Immediate Circuit Venting: Releasing just one button dumps the pilot air, prompting the directional control valve to return the cylinder to a safe, retracted state.

- Minimal Downtime Add-On: Implementing two-hand control often requires only a few pneumatic components added to your existing layout, making it a cost-effective safety upgrade.

The Core Components Needed for Dual Pneumatic Activation

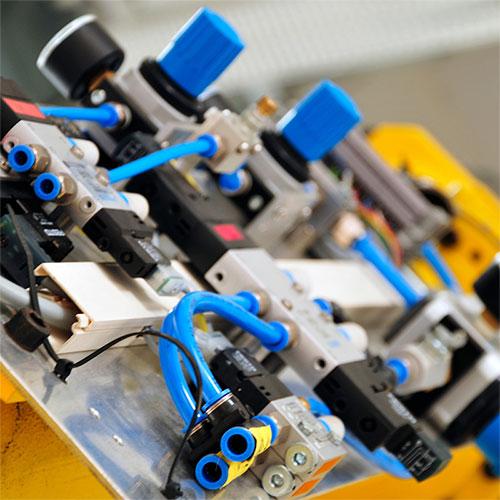

Once you recognize the safety boost that two-hand control provides, the next question is, “What parts do I need?” Although each machine may vary, the fundamentals are fairly consistent. At the heart of the system, two manually operated pneumatic valves work in tandem to send pilot air to a larger directional valve. If either valve is not pressed, the pilot air circuit breaks and no motion occurs. By focusing on these few key items, you ensure reliable two-hand activation.

- Two 3-Way Manual Push Valves: Often spring-return, these supply pilot air when pressed and vent it when released.

- 4-Way Directional Control Valve: The main spool that routes air to extend or retract the cylinder. It typically has a spring return to default.

- Double-Acting Cylinder (If Applicable): It extends when the directional valve shifts and retracts when pilot air is lost or reversed.

- Optional Sensors or Switches: Pressure or position switches can confirm the cylinder’s status, sending feedback to a monitoring system or PLC.

By assembling these components precisely, you guarantee motion only occurs under active, intentional engagement. This eliminates the risk of starting a cycle by mistake.

Designing the Circuit to Prevent Tie-Down and Misuse

While two-hand control is inherently safer, a cunning operator might try to defeat it—like jamming one pushbutton in place—thus negating the safety benefits. To combat this, you can introduce mechanical or pneumatic “anti-tie-down” features that detect whether a button is intentionally pressed or stuck.

A basic two-hand circuit can still be vulnerable if the operator blocks one valve permanently, pressing the other as needed to run the machine. This single-point activation cancels out the protective advantage. Hence, advanced designs incorporate secondary checks that reset the circuit after each stroke, ensuring both buttons must be released and then pressed again in unison for the next cycle.

- Interlocking Pneumatic Valves: Some systems place check valves or extra 3-way pilot valves in series, allowing air to flow only when each button is pressed within a short time frame.

- Mechanical Lockouts: Instead of purely pneumatic logic, a mechanical mechanism can lock the second button if the first button is held down for more than a fraction of a second.

- Continuous Monitoring: In integrated solutions, if a PLC or safety controller sees that one valve remains activated too long, it forcibly vents pilot air, halting the cylinder immediately.

Setting Speeds and Pressures for Controlled Extension

While two-hand control ensures intentional starts, you still need to verify that the cylinder’s actual movement is neither too fast nor too forceful. Even a safe circuit can cause injuries if the cylinder extends with excessive power.

Operators often assume any “safety” function automatically reduces speed and force, but that’s not always the case. You must still handle the fundamentals—flow controls and regulated pressures—to ensure the cylinder behaves predictably. By combining careful speed regulation with two-hand activation, you establish a dual layer of protection.

- Regulated Force: Lowering the supply pressure or installing a dedicated regulator for the extend stroke can significantly reduce accidental injuries. If a press or clamp only needs half its maximum force for a process step, dial it back so the cylinder can’t exceed safe limits.

- Flow Control Tuning: Installing flow controls on the exhaust side of the cylinder helps cushion movement. For heavier loads or larger cylinders, this prevents a “slam” that could pose a hazard, even if two-hand control is engaged.

This ensures the cylinder moves steadily into place rather than barreling forward, reducing the chance of harm if an operator miscalculates distances or inadvertently repositions a hand mid-cycle.

Maintaining and Auditing the System Over Time

Even the best-designed two-hand circuit can fail if left to operate under deteriorating conditions. Air leaks, clogged valves, or worn-out pushbuttons will eventually compromise safety. Regular inspections—both mechanical and pneumatic—are essential to confirm that your safety features remain intact. Over time, seals degrade, springs weaken, and pushbuttons may become sticky. Making audits part of your standard maintenance plan keeps the entire setup functioning as intended.

- Scheduled Leak Checks: A small leak in a pilot line can delay or prevent the release of pressure, defeating the immediate-stop function.

- Replacing Worn Parts: Pushbuttons with stiff or inconsistent actuation compromise the timing of two-hand engagement, so swap them out as soon as you notice a decline.

- Documentation and Training: Ensure every operator understands exactly how the two-hand circuit works and knows why tying down a button is dangerous

A well-structured two-hand control solution stands or falls on how diligently you keep it in prime shape. Proper upkeep preserves the safety advantages you worked so hard to establish.

Optimizing Pneumatic Control System Safety

Two-hand control circuits provide a proven, straightforward way to protect workers around presses, clamping fixtures, and other high-force pneumatic applications. By requiring both hands to initiate a stroke, the operator cannot physically place a free hand in the danger zone while the cylinder is in motion. Of course, this safety measure still relies on clean air lines, correct regulator settings, and functional components—a standard any robust pneumatic system should meet.

If you want guidance on selecting or customizing two-hand control components for your facility, Ellis/Kuhnke Controls is here to help. We can recommend the perfect combination of manual valves, pilot lines, and safety interlocks to align with your equipment’s force and speed demands. Remember: implementing a well-designed two-hand control circuit is more than just compliance; it’s a commitment to safeguarding your operators and reducing downtime from preventable accidents.

Related Reading

- Ellis/Kuhnke Controls

132 Lewis Street Unit A-2, Eatontown, N.J. 07724

Phone: 1-800-221-0714

Fax: 732-291-8154

Email: Info@ekci.com

- Home Pneumatic Controls Technical Info CAD Drawings Contact Us Pneumatic Timers Blog Site Map