Is Your Off-Delay Timer Causing Quality Control Problems?

Many technicians can recall that sinking feeling when a pneumatic cycle stalls at the worst moment—just as a critical part is about to be clamped or right when a conveyor is set to shift products down the line. In those moments, it often becomes clear that something as simple as an imperfect timer can unravel an otherwise well-planned system. Each misalignment forces teams to scramble for quick fixes or even halt production, draining morale and resources.

Many technicians can recall that sinking feeling when a pneumatic cycle stalls at the worst moment—just as a critical part is about to be clamped or right when a conveyor is set to shift products down the line. In those moments, it often becomes clear that something as simple as an imperfect timer can unravel an otherwise well-planned system. Each misalignment forces teams to scramble for quick fixes or even halt production, draining morale and resources.

Yet this scenario is anything but inevitable. When a pneumatic timer delivers precise and predictable intervals, it anchors the whole operation in reliability. Valves open and close exactly when they should, actuators stroke to the right positions, and sensors return consistent signals. That consistency is key to better throughput, fewer breakdowns, and calmer, more focused work conditions. Choosing the right timer for each application isn't just a technical nicety—it's the backbone of a cost-effective, stable process.

Why Are Timers So Crucial in Pneumatic Circuits?

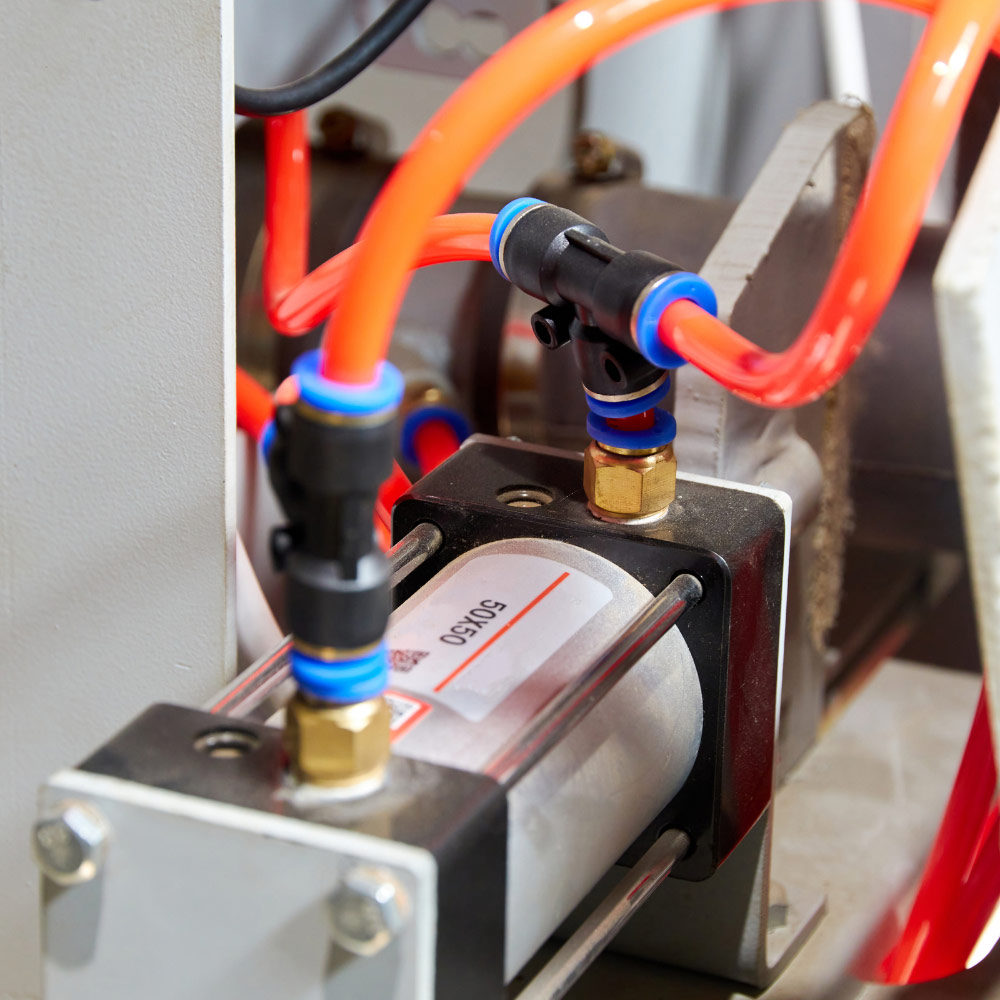

Timing in pneumatics goes beyond simply launching or halting airflow. Each stage in a sequence—such as feeding parts, sealing packages, or ejecting scrap—depends on the precise completion of the previous step. A packaging line, for example, might seal one carton before the next slides into position. If the off-delay timer that closes the sealing jaw runs a fraction too long, the next carton arrives prematurely, risking jams or missealed products. Conversely, a short on-delay could trigger the sealer too soon, damaging materials or missing the correct alignment altogether. A mistimed operation can cause quality control issues and expensive stoppages when each phase depends on a specific interval. A well-tuned timer keeps the chain of events flowing logically from one step to the next, saving both man-hours and frustration.

How Do Timers Cater to Ultra-Short Delays?

Some assemblies operate in bursts of activity just seconds apart. In these fast-paced environments—such as test benches for small components or quick-cycle product sorters—every tenth of a second can matter. That's why products like the Series 51 timer excel at shorter delays: adjustable from half a second to three minutes; it initiates timing by generating an internal vacuum. Once the air supply is removed, the timer resets automatically, reducing the need for constant manual intervention. In a busy assembly station, for instance, that means an operator can set a brief one-second delay for a blow-off nozzle and trust it will consistently eject parts without requiring daily recalibration. Meanwhile, where needs stretch slightly longer but remain under five minutes, a Mini-timer offers a dial-based adjustment and a visible countdown scale—ideal for repetitive tasks such as short curing cycles or quick leak tests.

What about Operations that Demand Longer Intervals?

A different set of challenges arises when timing cycles extend into hours. Certain processes—such as slow-fill systems for fluid dispensing, extended curing lines, or multi-hour safety checks—require timing solutions that maintain accuracy without drifting. The 54 Series timer steps up in these scenarios by relying on an internal air motor and gear system that delivers ±1% repeatability, even under varying line pressures. Imagine a large chemical blending operation where each batch must be stirred for precisely four hours before additional ingredients can be safely introduced. A timer that can handle up to 100 hours ensures no one on the floor has to hover anxiously over pressure gauges or guess when to add the next component. Furthermore, the rotor stop option lets a control valve pause the timer mid-cycle if a sensor detects an anomaly, preventing further processing until the issue is addressed—an invaluable safeguard when dealing with sensitive mixes or expensive materials.

Can One Timer Address Mid-Range Durations and Mounting Concerns?

For those who need times anywhere from a few seconds up to an hour, while also juggling space constraints or frequent reconfiguration, the Type PMT and PT series provide flexible mounting and adjustable spans. The PMT can be subplate- or panel-mounted, covering up to three minutes of on-delay (normally closed) timing. This design proves especially helpful in smaller control cabinets where real estate is tight. Still, reliability is paramount—such as a workstation that needs a two-minute purge cycle before the next product stage begins. On the other hand, the PT series addresses intervals of up to 60 minutes in either on-delay or off-delay forms. In a busy fabrication plant, operators might designate a 15-minute post-operation cool-down for welding stations, ensuring safe temperatures before the next shift starts. The PT timer's ability to be mounted vertically or horizontally helps technicians integrate it neatly into existing panels—no guesswork or messy retrofits required.

What Are the Keys to Selecting the Right Pneumatic Timer?

Finding the perfect fit starts by clarifying your timing window. If you need precision within a few seconds, a Series 51 or Mini-timer can handle rapid-fire tasks. The 54 Series is built to maintain near-constant accuracy for multi-hour spans, even with pressure variations. Next, decide whether your process needs an on-delay or off-delay design: an on-delay triggers airflow only after the set interval, whereas an off-delay keeps air flowing until that interval ends. Mounting is equally crucial: do you have space for a rear-mounted solution like the PMT, or do you need a panel-friendly PT with 1/8" NPT ports? Lastly, look at reset times and pressure limits to ensure compatibility with your broader setup. Mismatching these parameters can create inefficiencies that you're trying to avoid.

When these considerations are properly addressed, teams often see a dramatic reduction in unexpected machine halts or quality defects. Workers no longer have to stare at gauges or manually tweak valves, saving everyone time and hassle.

Related Reading

- Ellis/Kuhnke Controls

132 Lewis Street Unit A-2, Eatontown, N.J. 07724

Phone: 1-800-221-0714

Fax: 732-291-8154

Email: Info@ekci.com

- Home Pneumatic Controls Technical Info CAD Drawings Contact Us Pneumatic Timers Blog Site Map