How to Choose the Proper Optical Shutters for Pneumatic Control Systems

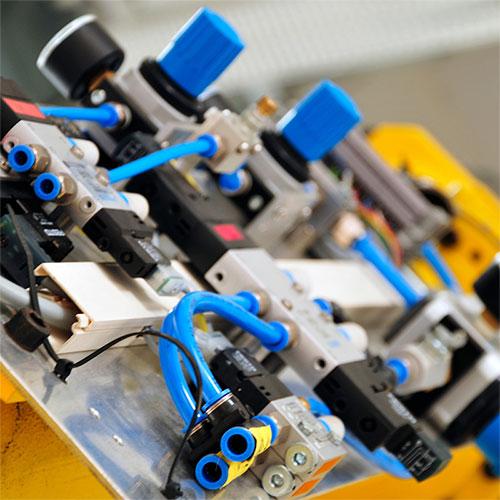

Many technicians and project managers grapple with unexpected disruptions when a laser or light beam fails to shut off on cue. These disruptions can be particularly daunting in pneumatic control systems, where accuracy, speed, and reliability must align seamlessly. Every minute spent troubleshooting a sluggish or unreliable shutter can feel like a race against time, especially when production lines or safety mechanisms hang in the balance.

Many technicians and project managers grapple with unexpected disruptions when a laser or light beam fails to shut off on cue. These disruptions can be particularly daunting in pneumatic control systems, where accuracy, speed, and reliability must align seamlessly. Every minute spent troubleshooting a sluggish or unreliable shutter can feel like a race against time, especially when production lines or safety mechanisms hang in the balance.

Choosing the right optical shutter often feels like a confusing maze of technical specs and performance claims. Yet precision in these decisions is crucial for avoiding the frustration of constant downtime and repeated maintenance. Properly matched optical shutters shield sensitive components and ensure every pneumatic process runs smoothly and safely. That reality underpins a crucial stance: selecting a shutter with the right design, responsiveness, and durability is vital for maintaining high-performance standards in pneumatic control systems.

Why Does Shutter Type Matter in Pneumatic Control Systems?

A pneumatic control system often requires rapid on-off cycles to manage laser or light beams. The speed of these cycles, combined with sustained system pressures, calls for components that can handle thousands—sometimes millions—of quick transitions. A shutter that’s too slow or prone to jamming disrupts this delicate interplay, resulting in reduced productivity and possible safety hazards. Looking at three unique shutter categories can clarify how each design addresses speed, energy savings, or ruggedness.

Which Factors Help Determine the Right Shutter?

Certain features make all the difference when evaluating different compact optical shutters for pneumatic applications. Paying close attention to the following can prevent misalignment later.

- Operating Temperature Range: Systems in cooler or more humid environments need shutters with reliable sealing and materials that remain stable through temperature swings.

- Mechanical Durability: Higher cycle counts (e.g., 10 million or 20 million) mean fewer mid-project failures and less disruption. Verifying the rated switching cycles ensures the shutter can withstand rigorous pneumatic demands.

- Closing Time: A shutter that can close in under 20 or 30 milliseconds helps preserve beam integrity and prevent timing-related errors.

- Mounting Options: Flanges or threaded holes can provide the stability necessary in pneumatic settings. Confirming alignment with existing hardware is crucial for trouble-free installation.

How Does a Bistable Shutter Aid Energy Savings?

Certain pneumatic setups require the light beam to remain blocked for extended periods without incurring high energy costs. A bistable optical shutter, such as product code CDR030, holds each end position magnetically. Because it does not consume power once it has reached an open or closed state, it significantly reduces heat and energy usage. This design is ideal in pneumatic control systems that spend prolonged time with the beam fully on or fully off. Key Highlights of a Bistable Shutter (CDR030):

- Energy-saving via currentless holding

- End positions maintained by permanent magnets

- Service life of up to 20 million switching cycles

- Typical closing time of around 30 ms

What if Fast Closing is the Top Priority?

Rapid cycling can be essential for applications where fleeting beam interruptions protect personnel or equipment. A self-restoring shutter with a closing time of around 30 ms delivers quick reaction capabilities. The product code D23 stands out for its dependable performance and high lifetime threshold of roughly 10 million cycles, offering a fast response with robust durability. Key Highlights of a High-Performance Shutter (D23):

- Self-restoring design

- Mechanical durability rated at 10 million cycles

- Fast closing time, typically 30 ms

- Potential for closing the aperture during power failure

When is a Miniature Shutter the Best Fit?

Space constraints can make incorporating bulky components into intricate pneumatic assemblies challenging. A compact option, like product code D16, can fit snugly into tight layouts while offering a quick closing time of under 20 ms. Despite its smaller form, the D16 line typically supports around 10 million switching cycles, making it a reliable choice for compressed setups that demand top-tier performance. Key Highlights of a Miniature Shutter (D16):

- Optimized for cramped spaces

- Fast closing time of ≤ 20 ms

- Service life of up to 10 million cycles

- Simple control interface for versatile integration

How to Match a Shutter to Specific Project Needs?

Synchronizing shutters with pneumatic mechanisms often demands a detailed checklist. To narrow down the best match:

- Assess Your Cycle Requirements: Prolonged or high-frequency use calls for shutters with higher mechanical durability and sturdy materials.

- Check Required Closing Speed: Rapid processes demand shorter shutter actuation times to maintain alignment with pneumatic events.

- Evaluate Power Constraints: A bistable design with currentless holding can dramatically reduce power usage if a system must conserve energy.

- Inspect Installation Parameters: Confirm that mounting brackets, diameters, and rotational angles mesh with the system’s geometry and engineering tolerances.

- Plan for Position Detection: Some shutters offer sensors to confirm end positions, streamlining real-time monitoring and preventing unexpected open or closed states.

Taking the Next Step for Reliable Light Control

Facing recurring shutdowns or precision errors caused by a poorly matched shutter is never satisfying. A balanced approach that weighs cycle rates, closing speed, and mounting space resolves these headaches before they start. Every step of this process guards against downtime and keeps pneumatic control systems running at peak efficiency.

Contact Ellis/Kuhnke Controls for a deeper conversation about these shutters. An expert recommendation often makes all the difference in finalizing the right choice, ensuring durable, precise light control in your pneumatic environment. Reach out today to start mapping a safer and more efficient path forward.

Related Reading

- Ellis/Kuhnke Controls

132 Lewis Street Unit A-2, Eatontown, N.J. 07724

Phone: 1-800-221-0714

Fax: 732-291-8154

Email: Info@ekci.com

- Home Pneumatic Controls Technical Info CAD Drawings Contact Us Pneumatic Timers Blog Site Map