What Exactly is a Pneumatic Controller?

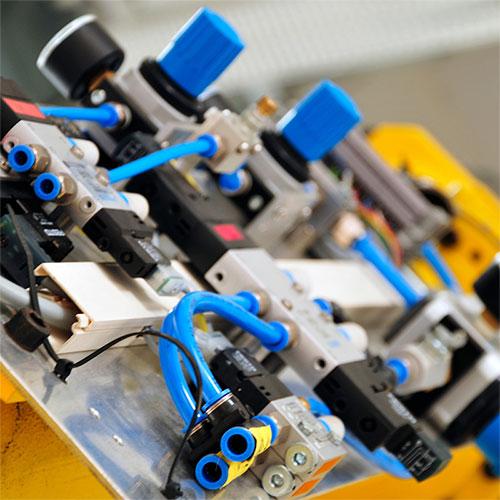

A pneumatic controller is a device that uses compressed gas—often natural gas or instrument air—to power and control valves. By modulating pressure within a system, the controller can open and close valves automatically, ensuring process variables (like liquid level or pressure) stay within desired limits. In-Depth Insight:

A pneumatic controller is a device that uses compressed gas—often natural gas or instrument air—to power and control valves. By modulating pressure within a system, the controller can open and close valves automatically, ensuring process variables (like liquid level or pressure) stay within desired limits. In-Depth Insight:

- Energy Source: Compressed natural gas or air provides the muscle to actuate the valve.

- Feedback Loop: The controller “reads” changes in pressure, level, or temperature and responds by adjusting valve position—no external power supply is needed.

- Versatility: Pneumatic controllers can be configured for many applications, from small separators to large transmission pipelines.

Why are Pneumatic Controllers So Common?

- Short Answer: They’re simple, robust, and self-contained—no extensive wiring or complex electronics required.

- Digging Deeper:

- Reliability: They tend to be highly durable, with fewer moving parts than many electronic systems.

- Adaptability: Natural gas is readily available on-site in production environments, making pneumatic power convenient and cost-effective.

- Intrinsic Safety: Without electrical components, there’s a reduced risk of sparks in potentially flammable or explosive conditions.

How Do Continuous and Intermittent Bleed Controllers Differ?

- High-Level Summary:

- Continuous Bleed: Constantly vent small amounts of gas while maintaining control.

- Intermittent Bleed: Only vent gas when the valve is actively adjusting position.

- A Closer Look:

- Continuous Bleed Controllers:

- Steady Emissions: They bleed gas around the clock, which can be a concern in some environmental contexts.

- Smooth Regulation: Ideal for processes requiring frequent, minimal adjustments—like maintaining a precise liquid level.

- Intermittent Bleed Controllers:

- On-Demand Emissions: Gas vents only when the valve transitions between open and closed.

- Rapid Response: Perfect for faster or more dynamic processes but can vent sizable bursts of gas when cycling frequently.

- Continuous Bleed Controllers:

- Key Takeaway: There’s no universal best type—your process requirements dictate which design is more efficient. Intermittent bleed systems can minimize overall emissions for slow processes that rarely need adjustment. In scenarios requiring constant fine-tuning, a continuous bleed model might prevent large surges of vented gas.

Where are Pneumatic Controllers Used?

- Production & Gathering: In upstream facilities, these controllers regulate the flow of gas and liquids through separators and dehydrators, maintaining stable operations even under varying reservoir pressures.

- Processing: Plants handling natural gas liquids or liquefied natural gas often prefer instrument air-powered devices for on-site reliability, though gas-powered controllers can still be found in certain sections.

- Transmission & Storage: From compressor stations to storage fields, pneumatic controllers maintain consistent line pressure and control valves for isolation or emergency shutdowns, ensuring smooth, reliable transport of gas over long distances.

- Distribution: Although pneumatic power is less common at this stage—where mechanical and electronic regulators might predominate—some systems still rely on smaller-scale pneumatic devices designed to route excess gas back into the pipeline rather than venting it to the atmosphere.

Are Emissions a Concern?

Yes, particularly with gas-powered units. Methane (the main component of natural gas) can be vented during regular controller operations. Why It Matters:

- Environmental Impact: Methane is a potent greenhouse gas. Managing or minimizing bleeds can have a noticeable positive effect on emissions reduction goals.

- Regulatory Considerations: Depending on the region, regulations may incentivize lower-bleed or instrument air controllers.

- Maintenance Factor: Well-maintained controllers—especially in clean gas service—often stay efficient for years, significantly reducing unnecessary leaks.

How Can I Reduce Emissions While Maintaining Efficiency?

- Instrument Air Conversion: Use compressed air instead of natural gas for the power supply. This effectively eliminates methane bleeds, though it requires additional infrastructure to generate or store air on-site.

- Upgraded Controllers: Low- or no-bleed designs focus on minimizing gas venting without sacrificing performance.

- Routine Inspection & Maintenance: Proactive checks can catch worn components before they lead to excessive venting or malfunction. Cleaning and replacing seals or diaphragms on schedule extend controller life and reliability.

Why Choose Ellis/Kuhnke Controls?

As a commercial partner serving industrial applications since 1962, we understand the value of dependable, user-focused solutions. Our pneumatic control lineup spans multiple options, from lower-bleed controllers to high-precision devices designed for swift, on-the-fly adjustments. Here’s what sets us apart:

- Proven Track Record: Decades of expertise in manufacturing and distributing pneumatic components.

- Tailored Solutions: We help specify the right controller type—continuous or intermittent bleed—for each unique application.

- Commitment to Quality: Our assemblies are built to withstand challenging conditions, maintaining safe operations for the long haul.

Your Path Forward

If your current control system leaves you worrying about reliability or emissions, it’s time to explore modern pneumatic solutions. Connect with Ellis/Kuhnke Controls to learn about retrofit options, new installations, or simply to get expert advice on optimizing your existing setup.

When every second counts—especially in critical industrial environments—a well-chosen pneumatic controller is far more than a piece of hardware; it’s peace of mind. Don’t let an outdated system slow you down. Reach out today to find a solution perfectly matched to your operational demands.

Related Reading

- Ellis/Kuhnke Controls

132 Lewis Street Unit A-2, Eatontown, N.J. 07724

Phone: 1-800-221-0714

Fax: 732-291-8154

Email: Info@ekci.com

- Home Pneumatic Controls Technical Info CAD Drawings Contact Us Pneumatic Timers Blog Site Map