Can Pneumatic Timers Actually Prevent Explosions in Chemical Plants?

Managing a chemical or petrochemical facility means facing constant, high-stakes decisions about safety. Every piece of equipment you select directly impacts workers' lives, regulatory compliance, and the facility's overall safety record. In explosive atmospheres, such as those found in refineries, chemical production plants, or pharmaceutical facilities handling volatile chemicals, a single misplaced spark isn't just a minor concern; it's a potentially catastrophic event.

Given these extreme conditions, the choice between pneumatic and electrical timers isn't simply technical—it's strategic. Pneumatic timers, relying entirely on compressed air and mechanical components, eliminate the inherent spark risk present in electrical timers, fundamentally transforming how safety is managed.

Why Electrical Timers Struggle in Explosive Environments

Electrical timers, even those specially designed for hazardous areas, pose an unavoidable risk of ignition due to internal arcing or static electricity. According to standards outlined in the ATEX Directive (2014/34/EU) and OSHA 29 CFR 1910.307, electrical equipment in hazardous environments must be heavily guarded with explosion-proof casings and complex wiring conduits. Despite these costly precautions, any deterioration or improper installation of electrical components still carries a significant risk.

In one documented chemical plant explosion, investigators traced the ignition source directly to an electrical timer relay. A subtle fault within the device sparked during regular operation, igniting flammable vapors that led to serious injuries and substantial structural damage. Such real-world incidents clarify why plant managers seek alternatives to electrical systems in hazardous zones.

Pneumatic Timers: Intrinsically Safe by Design

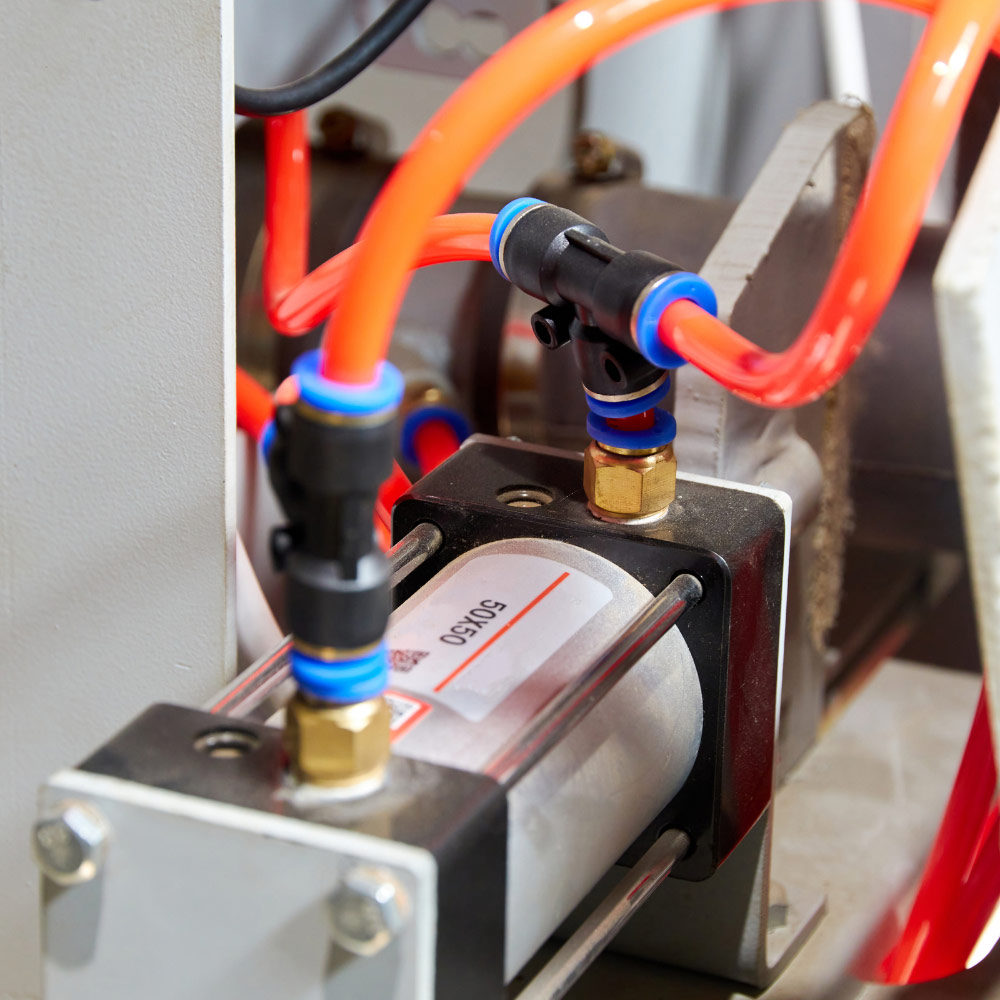

Pneumatic timers completely remove electrical ignition risks, fulfilling ATEX and IECEx requirements without complex adaptations or costly enclosures. The internal diaphragm or piston mechanisms are driven solely by compressed air, eliminating electrical components entirely. For instance, during routine maintenance cycles at an oil refinery, pneumatic timers control purging valves to clear hazardous vapors from reactors. These timers have repeatedly demonstrated their inherent safety advantages in audits, as there's no wiring or electrical failure risk present.

This mechanical simplicity doesn't just enhance safety; it significantly reduces installation errors, a frequent root cause of hazardous incidents. OSHA investigations consistently highlight improper electrical installation or wiring mistakes as leading causes of industrial accidents. Pneumatic systems dramatically reduce this human-error risk because their installation requires minimal specialized tools or complex setup procedures, thus decreasing workers' exposure to potential mistakes.

Compliance and Operational Advantages of Pneumatic Timers

Compliance with stringent regulations like ATEX, NFPA 69, and OSHA becomes straightforward with pneumatic timing systems. NFPA 69 explicitly requires equipment in explosion-risk areas to eliminate ignition sources. Pneumatic timers naturally fulfill this standard, ensuring regulatory audits proceed smoothly. For plant safety managers, this means less time worrying about potential violations and more confidence in overall compliance.

Operationally, the benefits are equally compelling. A chemical processing facility recently replaced electrical solenoids with pneumatic timers for critical valve actuation. The immediate impact was a reduction in maintenance downtime; pneumatic timers required fewer checks and adjustments due to their mechanical nature. Over several months, the facility recorded fewer disruptions, reduced operational costs, and notably improved personnel safety statistics, directly tied to the removal of electrical ignition hazards.

Reducing Human Exposure and Enhancing Safety Culture

Pneumatic timers also promote broader safety culture improvements by minimizing employee exposure to dangerous environments. Because pneumatic solutions are simpler to install and maintain, technicians spend significantly less time in hazardous zones. One refinery reported that, after adopting pneumatic timers, maintenance teams cut their exposure time by nearly half. Fewer tasks performed in risky conditions directly lowered incident rates and improved worker morale, creating a safer, more positive work environment.

A Measurable Safety Investment

In chemical production facilities, managing risk isn't only about avoiding catastrophe; it's also about reducing everyday hazards that cumulatively impact plant safety. In a notable petrochemical plant example, switching from electrically actuated valves to pneumatic timers dramatically reduced incidents involving sparks and minor ignition events. The outcome was measurable: fewer safety audits, a decrease in insurance premiums, and enhanced operational uptime. The plant's safety record improved significantly, underscoring pneumatic timers' tangible safety impact.

Embracing Pneumatic Timers as a Safety Standard

Ultimately, pneumatic timers represent more than a technical choice; they embody a strategic commitment to safety. By choosing a timing solution inherently designed for hazardous environments, chemical plants effectively eliminate one significant risk factor in their operations. Facility managers adopting pneumatic systems consistently report fewer hazardous incidents, streamlined regulatory compliance, and improved employee safety outcomes.

In hazardous chemical environments, safety choices aren't merely about compliance; they directly affect workers' lives and the facility's long-term operational health. Pneumatic timers stand out precisely because their mechanical nature and inherent spark-free design prevent the worst-case scenarios that all facility managers strive diligently to avoid. The careful integration of real-world examples throughout this analysis isn't incidental; it's essential proof of pneumatic timers' profound and practical safety benefits.

Choosing pneumatic timers isn't just wise; it's a necessary step towards a safer, more reliable industrial future.

Related Reading

- Ellis/Kuhnke Controls

132 Lewis Street Unit A-2, Eatontown, N.J. 07724

Phone: 1-800-221-0714

Fax: 732-291-8154

Email: Info@ekci.com

- Home Pneumatic Controls Technical Info CAD Drawings Contact Us Pneumatic Timers Blog Site Map