Why Pneumatic Visual Indicators Outperform Electronic Ones in Industrial Safety

If you're responsible for maintaining smooth, safe, and reliable industrial operations, you know firsthand how critical clear and immediate information about system status is. Any ambiguity can lead to costly downtime, safety hazards, or operational disruptions. Particularly with pneumatic systems, knowing instantly if air pressure is present or absent can mean the difference between efficient workflow and a sudden, unexpected halt. Perhaps you have faced situations where ambiguous visual signals caused confusion, delays, or even accidents. In those moments, you might have questioned if there's a more straightforward, clearer solution.

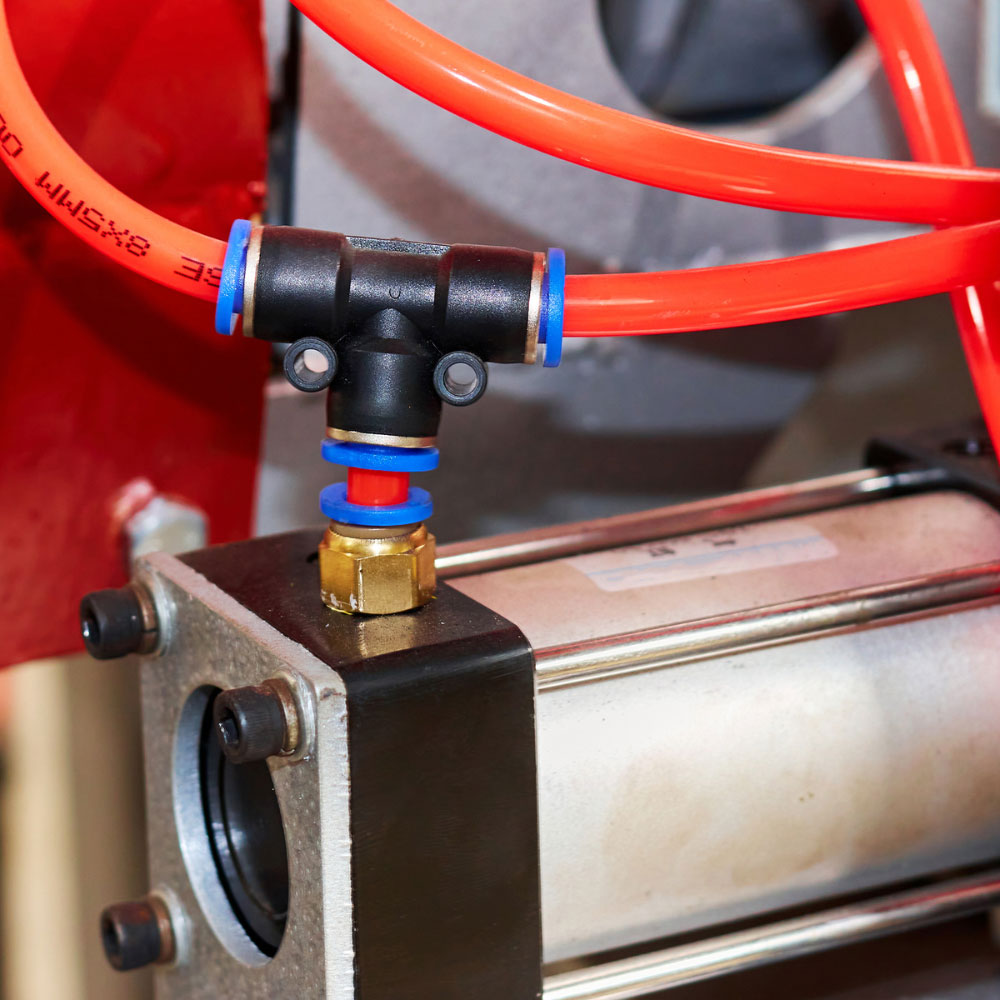

Addressing the need for immediate clarity, pneumatic visual indicators, such as EKCI's AL Series, offer a straightforward and reliable solution. These specialized devices eliminate guesswork, significantly enhance safety, and ensure operations run smoothly. By utilizing clear, two-color indicators powered solely by air pressure, the AL Series ensures your teams always know exactly what's happening in your pneumatic systems.

Why Immediate Clarity in Pressure Status Matters

Every experienced operator knows the frustration of unclear status indicators. Whether due to poor lighting, limited viewing angles, or ambiguous colors, uncertainty about system status isn't just inconvenient—it's dangerous and costly. Immediate, clear feedback about air pressure status directly affects safety and efficiency in your operations.

Specifically, instantaneous visual clarity helps you by:

- Detecting pressure loss or equipment malfunctions immediately, allowing rapid intervention.

- Preventing equipment damage from unnoticed fluctuations in air pressure.

- Enhancing safety for operators and maintenance personnel by eliminating guesswork or unnecessary manual checks.

Imagine a scenario in your plant: a critical valve fails to open because operators missed a pressure drop due to unclear indicators. The resulting downtime and potential damage could be substantial. Clear, unmistakable indicators, such as the AL Series, prevent exactly these scenarios.

Why Electronic Indicators Often Fall Short

Electronic indicators are often the default choice, yet they frequently introduce issues, particularly in environments that aren't electronically friendly. Hazardous conditions, moisture-rich environments, or chemically aggressive atmospheres pose constant threats to electronic equipment. You might recognize these common limitations:

- Spark risks hazardous, explosive atmospheres.

- Vulnerability to moisture, dust, and corrosive chemicals, leading to frequent malfunctions.

- Complex maintenance and troubleshooting requirements.

In practice, electronic indicators can become a significant source of frustration, especially in harsh industrial settings. Pneumatic systems require reliable indicators that withstand harsh conditions without introducing new safety concerns. Pneumatic visual indicators naturally fill this role by design.

How Pneumatic Visual Indicators Solve These Problems

Pneumatic visual indicators, such as the AL Series, operate with simplicity and reliability that electronics can't match in specific environments.

Here’s precisely why pneumatic indicators stand out:

- Purely Mechanical Operation: Operating solely on compressed air, these indicators have no electrical components, completely removing spark or ignition risks.

- Durable Design: Built for industrial panel mounting with an oil-tight seal, pneumatic indicators resist moisture, chemicals, and dust, significantly extending their operational lifespan.

- Immediate Visual Feedback: The AL Series uses a rounded, two-color lens that protrudes from the panel. It changes color instantly when air pressure is applied or removed, providing unmistakable clarity from any angle, up to a full 180° viewing range.

Consider your current setup: if operators constantly move around panels to discern status, or regularly deal with ambiguous or faded electronic indicators, switching to pneumatic visual indicators could dramatically enhance their daily operational experience.

Applications Where Pneumatic Indicators Excel

Practical applications for pneumatic visual indicators extend across numerous industrial sectors. Real-world examples clearly illustrate their value:

- Chemical or Pharmaceutical Plants: Environments with explosive atmospheres demand indicators that won't generate sparks. Pneumatic indicators, such as the AL Series, provide reliable status confirmation, eliminating explosive risks.

- Food Processing Facilities: Frequent washdowns and stringent sanitation requirements pose challenges to electronic components. Pneumatic indicators endure repeated exposure to moisture and cleaning chemicals without degradation, maintaining clear readability.

- Industrial Control Rooms: Operators managing complex systems appreciate instant, unambiguous feedback. Clear visual signals from pneumatic indicators enhance operational decision-making, minimizing errors and downtime.

Choosing the Right Pneumatic Visual Indicator

If you've decided to explore pneumatic visual indicators for your facility, the next step is to ensure the right fit for your specific needs. The AL Series, for example, provides versatile options:

- Pressure Range: Operates reliably from 20 to 120 PSI, compatible with the most pneumatic systems.

- Size and Connections: Choose between the AL15 (1/8 NPT ports) and the AL19 (10-32 Ports), depending on your system requirements.

- Color Combinations: Available in numerous clear, contrasting color pairs, such as red-green, amber-black, and yellow black, ensuring visibility tailored to your environment and preferences.

By carefully matching these specifications with your operational conditions, you can significantly enhance the clarity and reliability of your pneumatic system indicators.

Make Your Operations Safer and More Efficient

Implementing pneumatic visual indicators isn't just a technical improvement; it's a strategic enhancement of your entire operation. Clear, reliable indicators dramatically reduce risks, eliminate unnecessary downtime, and simplify maintenance. If your current electronic or unclear pneumatic indicators regularly cause frustration or operational delays, now is the ideal moment to reconsider your approach.

To fully understand how pneumatic visual indicators like EKCI's AL Series can improve your operations, consider reaching out to a specialized supplier or expert in pneumatic systems. They'll help ensure you choose the right solution, making your systems more transparent, safer, and more reliable for years to come.

Related Reading

- Ellis/Kuhnke Controls

132 Lewis Street Unit A-2, Eatontown, N.J. 07724

Phone: 1-800-221-0714

Fax: 732-291-8154

Email: Info@ekci.com

- Home Pneumatic Controls Technical Info CAD Drawings Contact Us Pneumatic Timers Blog Site Map