Pneumatic Systems: The Pulse of Precision in Microfluidic Control

Fluids flow effortlessly in the world around us—through rivers, pipelines, and even the human body. However, fluid control becomes a high-stakes challenge when fluid movement is scaled down to microscopic channels that are thinner than a strand of hair. In microfluidics, managing these flows with precision can mean the difference between a breakthrough diagnostic test and a failed experiment.

Fluids flow effortlessly in the world around us—through rivers, pipelines, and even the human body. However, fluid control becomes a high-stakes challenge when fluid movement is scaled down to microscopic channels that are thinner than a strand of hair. In microfluidics, managing these flows with precision can mean the difference between a breakthrough diagnostic test and a failed experiment.

This level of control is essential because microfluidic devices power technologies that shape modern medicine, environmental monitoring, and biochemical research. Pneumatic systems have emerged as the backbone of these devices, enabling precise, automated fluid management through pressure-driven circuits. Their unmatched accuracy and scalability redefine possibilities in cutting-edge scientific and medical applications.

The Mechanics of Microfluidic Mastery

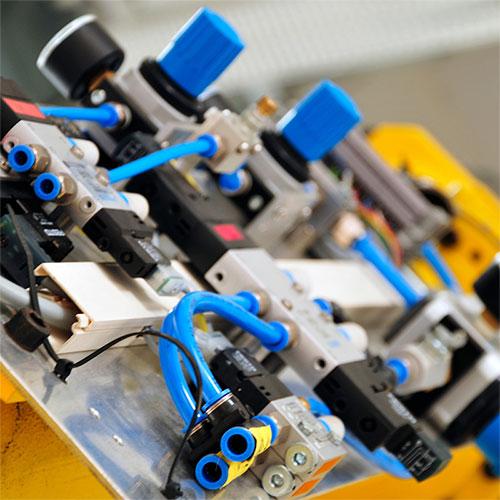

Pneumatic systems use pressure-driven elastomeric valves to control fluid movement. These valves act like mechanical switches, toggling open or closed depending on applied air pressure. This precision is essential in devices with channel widths as narrow as 10 micrometers.

For instance, in biochemical assays, pneumatic valves synchronize fluid flow to ensure reagents mix at exact intervals. This is achieved through pneumatic oscillators, which work like mechanical timers by cycling air pressure through a network of inverters. A standard three-stage pneumatic ring oscillator can maintain oscillation frequencies critical for precise microfluidic operation.

Real-World Impact: Automation Through Air

Automation in microfluidics depends on the timing precision provided by pneumatic circuits. Consider peristaltic pumps used in DNA sequencing: these pumps generate precise pulses by cycling pneumatic valves in a specific sequence. In one study, a pneumatic-driven microfluidic platform successfully managed over 100 independent fluid channels simultaneously with a timing accuracy of ±2 milliseconds. Key features of pneumatic systems in automation include:

- Precision Timing: Achieves fluid synchronization with millisecond-level accuracy.

- Automation Capability: Manages hundreds of fluid channels with minimal human intervention.

- Logic Operations: Supports fluidic counters and automated chemical synthesis.

Moreover, pneumatic systems support logic-based operations. Fluidic counters divide input pulses to control steps in automated chemical synthesis, performing tasks such as reagent mixing, heating, and analysis without human intervention.

Enhanced Technical Details and Metrics

To deepen technical credibility, here are additional specific metrics and examples:

- Operating Pressure Ranges: Typical pneumatic systems in microfluidics operate between 0.5 to 2 bar pressure.

- Valve Switching Speed: Many devices achieve switching speeds of less than 5 milliseconds.

- Fluid Flow Rates: Systems can regulate flow rates as low as nanoliters per minute for ultra-precise applications.

Future Horizons: Scaling Precision and Efficiency

The evolution of microfluidics depends on refining pneumatic control. Devices like autonomous environmental sensors and portable diagnostic tools are powered by pneumatic systems. A 2023 breakthrough involved a pneumatic-driven water quality monitoring system that operated continuously for six months without maintenance, underscoring its long-term stability and reliability.

Point-of-care diagnostics also benefit from this innovation. For example, a recent portable PCR device used pneumatic-driven microfluidics to detect pathogens in under 30 minutes, enabling fast disease detection in remote areas.

The Power Behind the Possibilities

Pneumatic systems are the invisible force enabling microfluidic innovations. Their ability to manage complex fluid dynamics with precision, scalability, and reliability continues to expand possibilities in medicine, environmental science, and beyond. As pneumatic-driven devices grow more advanced, they will redefine what’s possible in microscale fluid management.

Related Reading

- Ellis/Kuhnke Controls

132 Lewis Street Unit A-2, Eatontown, N.J. 07724

Phone: 1-800-221-0714

Fax: 732-291-8154

Email: Info@ekci.com

- Home Pneumatic Controls Technical Info CAD Drawings Contact Us Pneumatic Timers Blog Site Map