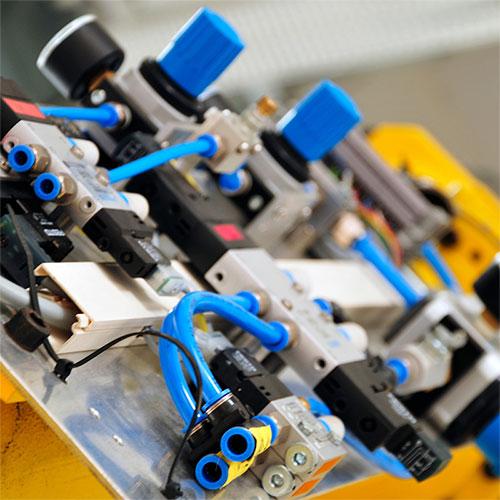

Basic Pneumatic Control System Types

Navigating the intricacies of pneumatic control systems reveals a spectrum from simple, robust setups to sophisticated, precision-oriented configurations. This journey from the foundational single pressure systems to the advanced pulse controlled systems showcases the adaptability of pneumatic technology in meeting diverse industrial requirements.

Navigating the intricacies of pneumatic control systems reveals a spectrum from simple, robust setups to sophisticated, precision-oriented configurations. This journey from the foundational single pressure systems to the advanced pulse controlled systems showcases the adaptability of pneumatic technology in meeting diverse industrial requirements.

Foundational Simplicity: Single Pressure Systems

Single Pressure Systems are the cornerstone, epitomizing both simplicity and reliability in operation. Central to these systems is a singular valve, typically solenoid-actuated, which governs compressed air flow from its source to the application. This valve's binary operation—open to allow airflow, closed to stop it—ensures consistent pressure throughout the system. Designed for straightforwardness, these systems facilitate ease of maintenance and boast inherent reliability. They are particularly indispensable in scenarios demanding a uniform and constant pneumatic force, making them a fundamental choice for various industrial applications.

- What Makes It Unique? Single valve operation ensures straightforward pressure management. Cost-effective and easy to maintain due to minimal components.

- Best Suited For: Applications demanding constant pressure, like powering pneumatic tools.

Stepping Up Control: Dual Pressure Systems

Elevating the capabilities of pneumatic control, dual pressure systems mark a significant advancement by incorporating a dual-valve mechanism to manage variable pressures adeptly within the same network. This innovation builds on the foundational simplicity of single pressure systems and introduces a new dimension of operational flexibility. By utilizing two valves, these systems can precisely control and alternate between different pressure levels, catering to the dynamic requirements of various industrial processes. This ability to adjust and maintain multiple pressures enhances the system's versatility, allowing for tailored pneumatic solutions that can meet the nuanced demands of complex applications, thereby representing a significant stride toward greater adaptability and control in a pneumatic system design.

- Key Advantages: Versatility in creating two separate pressure zones. Enhanced precision in pressure control compared to single pressure systems.

- Ideal Applications: Suitable for automated manufacturing where different tasks require distinct pressure settings.

Precision and Flexibility: Modulated Pressure Systems

Modulated Pressure Systems are the apex of precision and control within pneumatic technologies, utilizing an intricate array of valves to facilitate fine-tuned pressure adjustments. This design allows for a highly customizable approach to controlling airflow and pressure, ensuring that even the most subtle changes in operational requirements are met with precise responses. Such systems are pivotal for applications demanding exact control over pressure levels, providing flexibility and accuracy unmatched by simpler pneumatic setups.

- Distinct Features: Precision in controlling a wide range of pressures. Tailored for applications where accuracy in pressure modulation is critical.

- Application Highlight: Spray painting and fuel injection systems, where precise flow control directly impacts outcome quality.

The Peak of Responsiveness: Pulse Controlled Systems

Pulse controlled systems represent the zenith of responsiveness in pneumatic control technology. These systems are characterized by using rapid pulses of compressed air to actuate mechanisms, offering unparalleled speed combined with pinpoint accuracy. Engineered for scenarios where the margin for error is minimal and the need for swift, precise action is critical, pulse controlled systems excel. They embody the cutting edge of pneumatic control, providing solutions where traditional methods fall short and opening new avenues in automation and process control.

- Unique Characteristics: Rapid pulses of air enable high-speed actuation. Exceptional precision and quick response times.

- Optimal Use: Robotic assembly lines and high-speed sorting processes, where precision and speed are non-negotiable.

EKCI Pneumatic Control Systems

The evolution of pneumatic control systems from single pressure to pulse controlled configurations illustrates a trajectory toward increasing sophistication and precision. This range of systems underscores the versatility of compressed air as a powerful tool in automation, capable of addressing a broad spectrum of industrial challenges.

Related Reading

- Ellis/Kuhnke Controls

132 Lewis Street Unit A-2, Eatontown, N.J. 07724

Phone: 1-800-221-0714

Fax: 732-291-8154

Email: Info@ekci.com

- Home Pneumatic Controls Technical Info CAD Drawings Contact Us Pneumatic Timers Blog Site Map