Pneumatic Timers are the Key to Industrial Safety and Efficiency

Safety and operational efficiency are paramount in oil and gas extraction or mining environments. When traditional electrical systems pose a significant risk due to potential sparks and fire hazards, pneumatic timers offer a safer, more reliable solution. These devices operate without electricity and have become the preferred choice in hazardous environments. But why are they indispensable?

Safety and operational efficiency are paramount in oil and gas extraction or mining environments. When traditional electrical systems pose a significant risk due to potential sparks and fire hazards, pneumatic timers offer a safer, more reliable solution. These devices operate without electricity and have become the preferred choice in hazardous environments. But why are they indispensable?

Pneumatic timers provide unmatched reliability and precision, which are essential in preventing accidents, improving efficiency, and maintaining safety standards in industrial operations where electricity is dangerous or unavailable.

Pneumatic Timers: The Core of Hazardous Environment Solutions

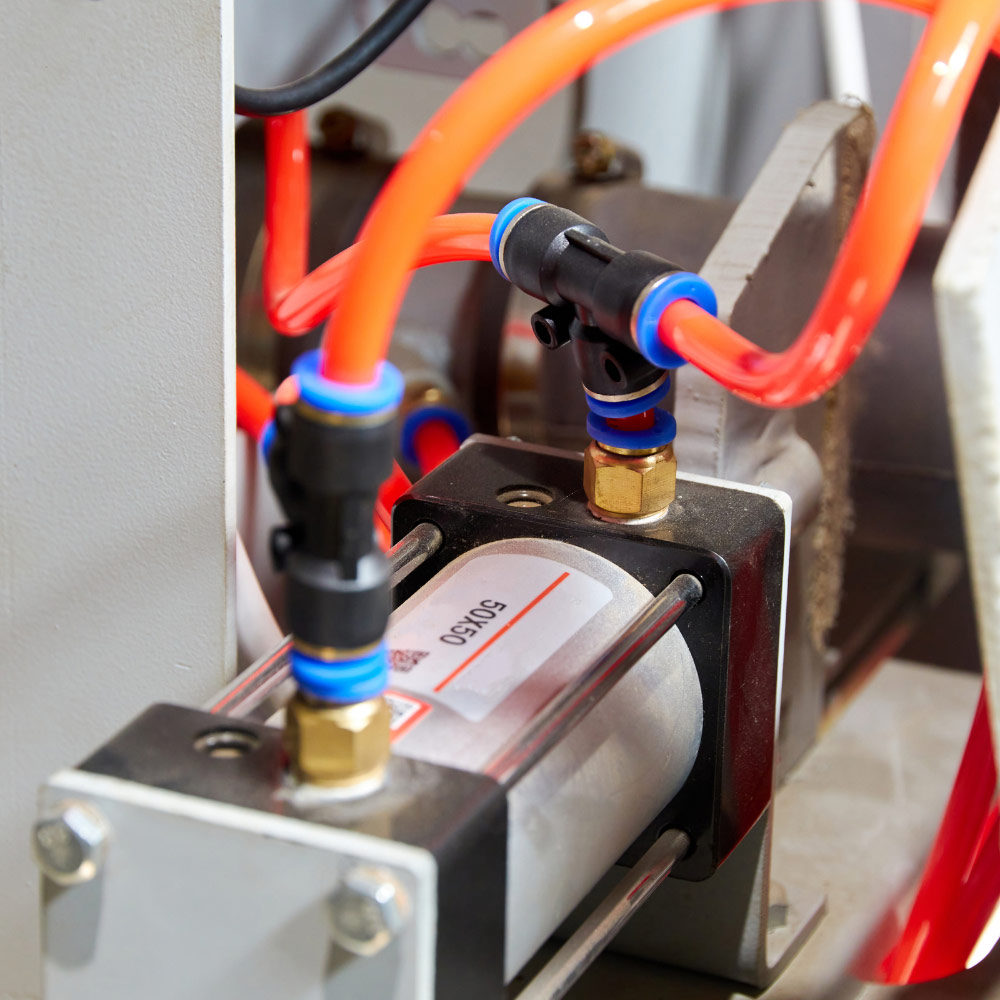

Pneumatic timers are designed to operate without electricity, providing control over industrial processes using compressed air instead of electrical currents. In environments prone to gas leaks or flammable substances, eliminating electrical systems is not just a convenience—it is a necessity for preventing catastrophic incidents. The urgency of their implementation cannot be overstated.

These timers can control the timing of air pressure releases with high accuracy, ensuring that operations remain smooth and consistent. They are an indispensable component of pneumatic control systems in hazardous locations where electrical equipment could result in dangerous sparks.

Why Pneumatic Timers Are Superior to Electrical Systems

While electrical timers work in many standard environments, they introduce serious risks in hazardous industrial locations. Electrical sparks can ignite gases, causing explosions or fires. By contrast, pneumatic timers eliminate the need for electricity, ensuring safer and more efficient operations.

Pneumatic timers provide precision every time, regardless of environmental conditions, ensuring processes are carefully timed and controlled. This reliability and precision instill confidence in their use, making them the best solution for industries like oil and gas or mining.

The Critical Role of Pneumatic Timers in Reducing Risk

Safety should never be compromised in industrial environments. Pneumatic timers are inherently safer because they remove the risks associated with electrical currents. They are also designed to withstand extreme conditions without failing, which is critical in locations where equipment failure could result in severe accidents or even fatalities.

For example, introducing even a single electrical spark could result in catastrophic consequences on an offshore oil rig, where flammable gases are prevalent. Pneumatic timers eliminate this risk by using compressed air instead of electricity. Their precision ensures that industrial systems can continue operating without interruptions, protecting workers and equipment from potential dangers.

Enhancing Operational Efficiency with Pneumatic Timers

Beyond safety, pneumatic timers offer unparalleled operational efficiency. Their uncomplicated design makes them incredibly reliable and easy to maintain, reducing downtime caused by electrical malfunctions. Accessing and maintaining electrical systems can be extremely costly and challenging for industries operating in remote areas, such as deep underground mines or offshore rigs. Pneumatic control systems eliminate these issues, ensuring operations run smoothly, even in challenging environments.

Their precision also ensures that air-based systems work at optimal timing intervals, reducing the likelihood of system errors. For example, in a mining operation, where ventilation systems must be controlled to manage air quality, a pneumatic timer ensures these systems operate consistently and efficiently without the risk of electrical failure, giving you the confidence that your operations are running smoothly.

Pneumatic Timers Are the Safer, More Reliable Choice

Pneumatic timers are the key to ensuring safety and operational efficiency in hazardous environments. Their ability to operate without electricity removes the risk of electrical malfunctions and sparks, providing peace of mind that your operations are in safe hands. For oil, gas, mining, and other industries, pneumatic timers offer operational precision and unmatched reliability, ensuring you can focus on your core business.

If your operation demands the safest, most efficient solution, pneumatic timers are the answer. Contact us today to explore how pneumatic control systems can benefit your industrial processes.

Related Reading

- Ellis/Kuhnke Controls

132 Lewis Street Unit A-2, Eatontown, N.J. 07724

Phone: 1-800-221-0714

Fax: 732-291-8154

Email: Info@ekci.com

- Home Pneumatic Controls Technical Info CAD Drawings Contact Us Pneumatic Timers Blog Site Map