How Do I Properly Size and Control My Pneumatic Cylinder to Avoid Slow Speeds and Banging?

When a pneumatic cylinder slams at the end of its stroke or drags sluggishly during movement, it can disrupt production, damage equipment, and increase overall operational costs. Many engineers and operators feel frustrated when pinpointing the root cause, especially if they’ve already invested in quality parts but still wrestle with inconsistent performance. The experience often boils down to overlooked details in cylinder sizing, airflow management, or end-of-stroke cushioning.

When a pneumatic cylinder slams at the end of its stroke or drags sluggishly during movement, it can disrupt production, damage equipment, and increase overall operational costs. Many engineers and operators feel frustrated when pinpointing the root cause, especially if they’ve already invested in quality parts but still wrestle with inconsistent performance. The experience often boils down to overlooked details in cylinder sizing, airflow management, or end-of-stroke cushioning.

Choosing the right bore, length, and flow controls can transform an unpredictable cylinder into a smooth, high-speed actuator. This matters because wasted air, equipment wear, and sudden banging hurt efficiency and create safety hazards. Below, we’ll explore key strategies—aligned with our experience at Ellis/Kuhnke Controls—to size and manage cylinders for stable, reliable motion.

Why Oversized Cylinders Cause More Harm Than Good

Before diving into airflow settings or dampening methods, it’s crucial to acknowledge how an incorrectly sized cylinder can derail your entire setup. Oversized cylinders might seem safer or more versatile, but the reality is that excessive bore diameters lead to sluggish speeds and increased air consumption. If you’re constantly hearing a “clank” when the rod extends or retracts, there’s a good chance your system is struggling under the burden of too much capacity.

- High Air Demand: When a cylinder’s bore is larger than necessary, each stroke requires more air volume than your compressor or plant supply can reliably deliver, potentially causing pressure drops throughout the system.

- Inefficient Use of Force: Although a bigger cylinder can provide higher force, much of that force may be wasted if your application only needs a fraction of it. This overshoot often results in rapid acceleration and hard stops at either end.

- Higher Wear & Tear: Every time an oversized cylinder bangs into its end caps, internal seals and mechanical components endure extra stress, shortening the cylinder’s lifespan.

Always start by calculating the minimum force required for each phase of your operation, factoring in load weight, friction, and any additional force needed for safety margins. Then, add a moderate safety factor—don’t just double or triple it without reason. This balanced approach ensures you have enough power for unexpected load variations without introducing unnecessary bulk or slowdowns.

Establish a Solid Baseline with Air Pressure & Flow

Even the best cylinder sizing won’t solve performance problems if your air supply is inconsistent or poorly regulated. After choosing the correct bore, the next step is ensuring your compressor output and downstream components deliver a stable, clean source of air.

Air that’s free of contaminants, delivered at the right pressure, and consistently maintained is the lifeblood of any pneumatic system. Without it, you risk sluggish starts, random pressure drops, and those dreaded mid-stroke stalls. By focusing on both filtration and regulation, you set a strong foundation for smooth cylinder operation.

- Pressure Regulation: Position a regulator near the point of use to minimize pressure fluctuations. Monitor gauge readings closely to confirm you’re within the recommended PSI range for your cylinder’s specifications.

- Filtration & Moisture Removal: Use a high-quality filter to prevent debris and liquid from reaching critical valves or cylinder seals. If your environment accumulates moisture quickly, opt for automatic drains, as consistent draining ensures stable airflow.

- Flow Capacity Checks: Confirm that your main supply line and fittings can deliver sufficient cubic feet per minute (CFM) to match your cylinder’s speed requirements. If multiple cylinders and valves share the line, consider whether peak demand might choke airflow at certain times.

When your air preparation is dialed in—meaning the regulator, filter, and flow elements are correctly sized—your cylinder can operate at its intended speed. This alignment with proper cylinder dimensions keeps motion fluid and precise, preventing abrupt starts or stalls that eventually lead to banging.

Fine-Tune Movement with Flow Controls and Cushions

Once you’ve nailed your basic air prep and confirmed you’re not overloading the system with an oversized cylinder, it’s time to refine how air enters and exits the actuator. This stage is where you transform brute force into controlled movement.

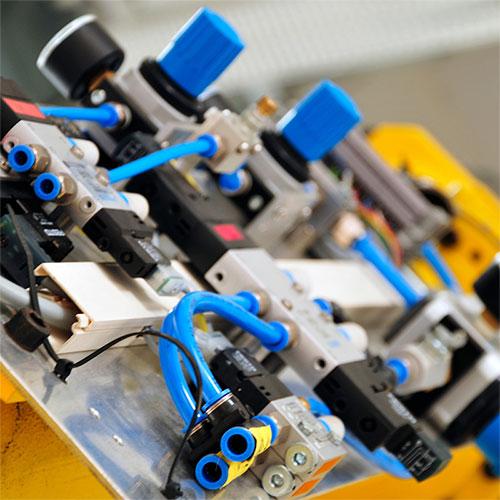

Flow controls primarily manage exhaust air—an often-overlooked factor in achieving smooth and predictable travel. Whether integrated into the cylinder design or added as external accessories, cushions help dissipate the rod’s kinetic energy. Together, these features prevent the “hammer effect” often heard when a cylinder completes its stroke.

- Adjustable Exhaust Flow: Throttling the air on the cylinder’s outgoing side slows rod movement near the stroke endpoints, avoiding abrupt slams. By installing one-way flow controls, you let air in freely but require it to exit through an adjustable needle valve, independently regulating extension or retraction speed.

- Built-In Cushioning: Some cylinders have internal cushions that engage as the piston nears the cap or rod end. These help absorb momentum, reducing noise and wear. If the built-in cushions aren’t sufficient, external shock absorbers or special end-of-stroke attachments can add even more damping.

- Practical Outcome: With these controls in place, your cylinder glides rather than crashes into position, sparing seals and rods from undue stress. This approach also stabilizes cycle times, enhancing overall repeatability and safety.

Prevent Abrupt Starts via Careful Air Preparation

Achieving gentle stops is only half the battle—avoiding jolting starts is equally important. While you’ve already set up filtering and regulating for steady airflow, adding certain valves and design considerations ensures a gentler ramp-up whenever the system is first pressurized.

When a pneumatic circuit goes from zero to full pressure in a blink, the first stroke of the cylinder can be unexpectedly forceful. This initial jolt can damage mechanical linkages or pose a safety hazard to nearby operators. You can minimize sudden spikes at startup by incorporating a few strategic components and design tweaks.

- Soft-Start/Dump Valves: These valves introduce air gradually to the system, allowing pressure to build slowly rather than in a single surge. They provide an easy way to exhaust pressure for maintenance or emergency stops.

- Manual Shutoff Relief Valves: These are lockable for safety, ensuring the air supply is isolated when servicing. They relieve air downstream so no latent pressure lingers, preventing a violent first stroke at re-energization.

- Staged Pressurization: Use multiple regulators or sequential valve actuation to fill lines step-by-step. This method is particularly helpful in complex setups with multiple cylinders or sensitive instrumentation.

Even the perfectly sized cylinder with well-tuned flow controls can slam unexpectedly if it’s fed high-pressure air all at once. Eliminating these abrupt starts ensures consistency from the first cycle to the thousandth, protecting both machinery and personnel.

Bringing It All Together for a Stable, Efficient System

Now that you’ve considered size, air supply, flow control, and startup dynamics, it’s time to see how these pieces form a cohesive strategy. Skimping on any single element can unravel the benefits of the others. A well-designed pneumatic system balances power requirements against airflow capacity. It also invests in precisely managing how air enters and exits the cylinder at startup and during normal operation. When done correctly, the result is minimal banging, stable speeds, and a cylinder that performs as expected day in and day out.

Even the best setup degrades without upkeep. Regular inspections of filters, seals, and cushion adjustments go a long way toward preserving smooth motion. By catching leaks or contamination early, you ensure your pneumatic system continues to run at peak efficiency.

Prevent Slow Cylinder Speeds: Here’s How to Fine-Tune Your Flow Controls

Missteps in pneumatic system design are often traced back to a mismatch between cylinder size and air management methods. You can achieve quick yet gentle strokes that protect your equipment by optimizing each stage—sizing, airflow regulation, and motion damping. If you’re unsure where to begin or need a custom solution, Ellis/Kuhnke Controls specializes in tailoring pneumatic components for both new and existing installations. The difference between a banging cylinder and a smooth one often lies in these thoughtful details—so don’t settle for constant adjustments or repairs. Reach out, and let’s set up a system that meets your production goals without the drama.

Related Reading

- Ellis/Kuhnke Controls

132 Lewis Street Unit A-2, Eatontown, N.J. 07724

Phone: 1-800-221-0714

Fax: 732-291-8154

Email: Info@ekci.com

- Home Pneumatic Controls Technical Info CAD Drawings Contact Us Pneumatic Timers Blog Site Map