Overcoming the Limitations of Pneumatic Control Systems

By design, pneumatic controls are meant not to be overly complicated. Their simplistic design makes the systems beneficial for modern building managers, but the devices do come with some drawbacks. Being mindful of your needs, and the benefits and limitations of pneumatic controls are necessary parts of choosing pneumatic control systems.

Although simplistic in design, pneumatic systems require regular maintenance that must be administered by someone that knows what they are doing. There are two main types of maintenance. You must make sure that the air supply is dry, reliable, and clean. Secondly, you must carry out a strict routine of preventative maintenance. Maintenance of pneumatic systems includes inspecting and adjusting all components of the system including pneumatic valves and all other pneumatic controls. Maintenance should be performed every couple of years.

Updating systems is also vitally important. Older systems use outdated technologies that are difficult, and sometimes not possible to replace. At a certain point, a system becomes unserviceable. Avoid pulling out systems and replacing them by maintaining new and updated parts.

Limitations experienced when using pneumatics are significantly reduced with maintenance and energy. Take care of your systems, and they will work optimally for prolonged periods.

Pneumatic Controls

- Waste Less Energy Using Pneumatic Control Systems

Learning about the most common ways in which air is lost will help you identify problems early on. We sell pneumatic control systems, like pneumatic valves, that are designed to have systems run optimally.

- Why Pneumatic Systems are Essential for Modern Automation

- Choosing Pneumatic Control Valve Types

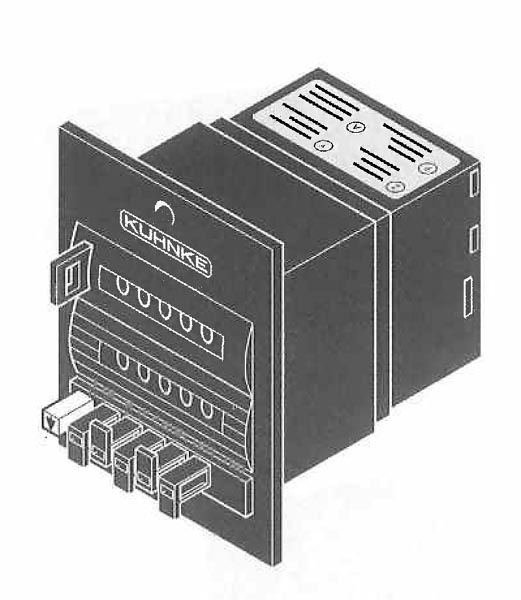

- Ellis/Kuhnke Controls

132 Lewis Street Unit A-2, Eatontown, N.J. 07724

Phone: 1-800-221-0714

Fax: 732-291-8154

Email: Info@ekci.com

- Home Pneumatic Controls Technical Info CAD Drawings Contact Us Pneumatic Timers Blog Site Map