Choosing Pneumatic Control Valve Types

In most pneumatic systems, pneumatic valves control the rate, pressure, and direction of air through lines. There are many options available for valve types, and each is used to achieve a particular purpose. This means that pneumatic valves are not to be used interchangeably. The correct pneumatic valve is needed for your unique job.

Some valves focus on regulating flow as it passes through another section. Other types are meant to allow for a flow to stop, pass, or change direction. Traditional flow controls have apertures that can change. As they close, they slow the flow rate, and as they increase in aperture size so does the flow rate.

The pneumatic flow control valve offers increased functionality when compared to traditional control valves. A flow control valve allows users to regulate both pressure and flow, which cannot be done with traditional types.

The primary function of a flow control valve within a pneumatic circuit is to reduce the overall rate of flow in designated sections. The result is a slower actuator speed.

Your needs should determine which valve you use. Common control valves include:

Traditional control valves: applications of this valve are limited to fully open, fully switched, or fully closed. They have a simple design.

Needle Control Valves: this is considered a variable control valve that is not considered pressure compensated. The valve creates a pressure difference between down and upstream.

Ball Valves: these valves have a hollow, perforated, and pivoting ball that controls flow. When the hole of the ball lines up with the flow, it opens. After the ball pivots 90-degrees it becomes closed.

Pneumatic Controls

- Flow Control Valves for Pneumatic Control Systems

Flow alters the rate, and pressure changes the force of the device. Valve positions direct the actuator. Pneumatic control systems help control the flow of air.

- Waste Less Energy Using Pneumatic Control Systems

- Why Pneumatic Systems are Essential for Modern Automation

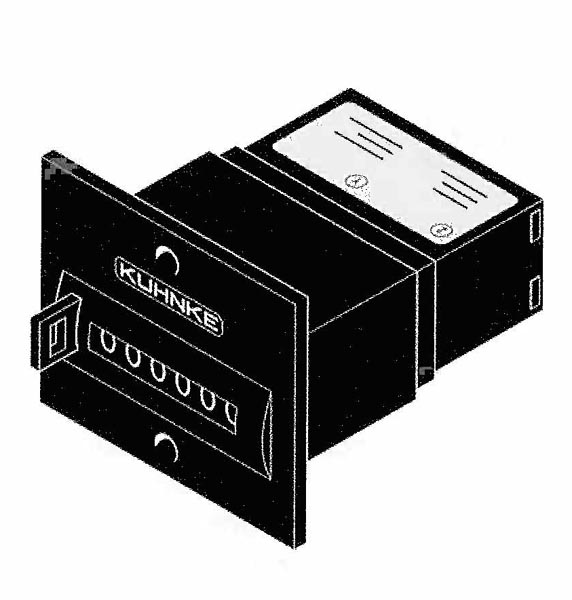

- Ellis/Kuhnke Controls

132 Lewis Street Unit A-2, Eatontown, N.J. 07724

Phone: 1-800-221-0714

Fax: 732-291-8154

Email: Info@ekci.com

- Home Pneumatic Controls Technical Info CAD Drawings Contact Us Pneumatic Timers Blog Site Map