Actuators and Pneumatic Valves

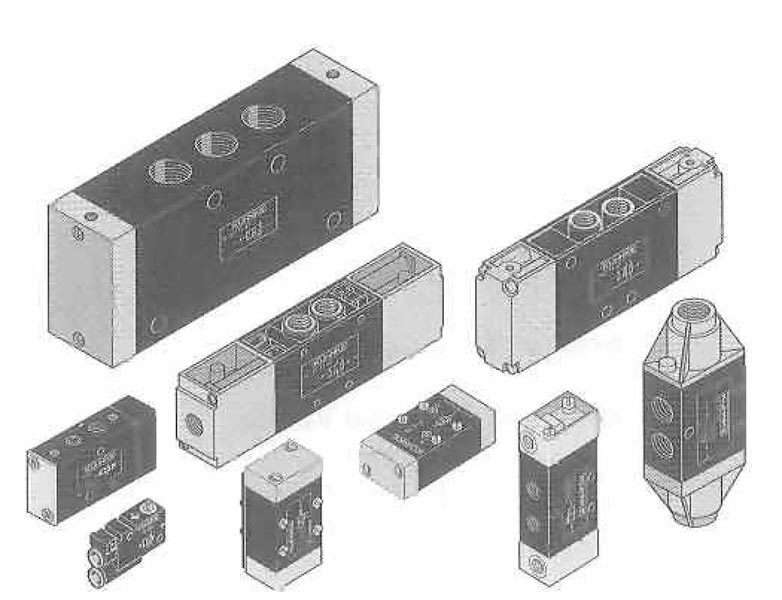

Pneumatic valves are categorized by the type of actuator they use. Actuators fall under three categories: air-operated, electromagnetic, and mechanical. This article will discuss different types of pneumatic valves based on the actuators they use.

Air-Operated Valves

Air-operated valves are ideal when there is a high output demand but no need for electricity. They can be used remotely. These valves are commonly used in fertilizer manufacturing facilities and chemical factories. In chemical factories, these valves help to avoid exposure to the wrong substance, eliminating danger to operators. In fertilizer manufacturing facilities, air-operated valves ensure workers are kept from noxious nitrogen compounds.

Solenoid Valves

Solenoid valves use an electric signal to open and close. In a pneumatic system, they control airflow, while in a hydraulic one, they control liquid. These valves are often used in industrial factories for manufacturing because they require a consistent temperature. However, solenoid valves can work in a changing atmosphere. They are often used in cars to start the ignition. Other applications for these types of valves are dishwashers and irrigation systems. Solenoid valves are popular because of their durability and versatility.

Mechanical Valves

These valves are also referred to as hand-operated valves because they use manual power. Energy is applied to mechanical valves by using your feet or hand to move them. This is done by either pressing a button with your palm or applying a push-pull motion. If electricity use would be dangerous, it’s best to go with a hand-operated valve. They can be used for liquid flow or airflow.

Related Reading about Pneumatic Valves

- Ellis/Kuhnke Controls

132 Lewis Street Unit A-2, Eatontown, N.J. 07724

Phone: 1-800-221-0714

Fax: 732-291-8154

Email: Info@ekci.com

- Home Pneumatic Controls Technical Info CAD Drawings Contact Us Pneumatic Timers Blog Site Map