What are the Top Reasons to Use Pneumatic Systems?

Industrial pneumatic control systems may seem like complex and confusing machines, but that is not the case. The system's function and components are relatively simple to grasp (especially when you break down individual device types. Because of the simplicity of these systems, plus their many benefits, many industries favor these devices. They seamlessly Incorporate them into equipment and machines. These systems are great for keeping maintenance costs down. Why else should you consider using pneumatic control systems?

Pneumatic control systems offer high levels of safety, especially when compared to gas and electrically powered systems. There is a minimal chance for fire and explosion. Systems that use hydraulic oil are much more likely to have accidents.

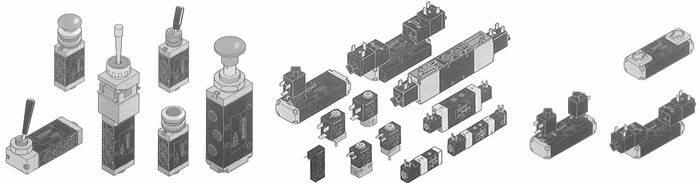

The simplicity of these systems allows for easy design and control. Machines can be designed with standard cylinders and other basic components that operate with a simple on/off switch. Systems are often comprised of components, including pneumatic valves, pneumatic actuators, and receivers.

The systems are incredibly reliable. Gas is a compressible substance, so pneumatic control systems are not prone to shock damage. Gas also can absorb large amounts of force. It is easy to store gas so machines can continue to run even after electrical power is lost.

Related Reading

- Ellis/Kuhnke Controls

132 Lewis Street Unit A-2, Eatontown, N.J. 07724

Phone: 1-800-221-0714

Fax: 732-291-8154

Email: Info@ekci.com

- Home Pneumatic Controls Technical Info CAD Drawings Contact Us Pneumatic Timers Blog Site Map