Top Tips for Maintaining and Cleaning Pneumatic Solenoid Valves

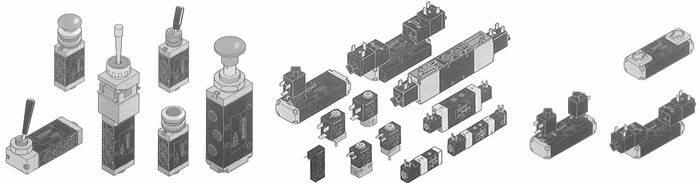

Although pneumatic control systems are relatively safe and reliable, there is still the chance that issues can occur. It might be impossible to prevent all issues from occurring, but they can be greatly minimized with adequate and proper cleaning and maintenance. One of the most important things to maintain is the cleanliness of a pneumatic solenoid valve.

How do you properly clean pneumatic valves?

First, get a dry and soft piece of lint-free material. Use this to remove any excess moisture from housings and fittings. The point of keeping surfaces dry is to reduce corrosion and keep solenoid pneumatic valves moving smoothly for many years. Machinery should be placed into cold shutdown when valves are not receiving flow or voltage. Doing this is a vitally important part of safety.

If corrosion accumulates, it needs to be removed as part of the cleaning process. If corrosion damages valves, they need to be removed from work because corrosion spreads to surrounding system parts. It is also important to check the inside of valves for debris.

It is important to mention that some pneumatic solenoid valves are more resilient against dirt than other pneumatic valves. The way installation is initiated directly impacts the number of dirt that a valve collects. When you attach solenoid pneumatic valves to connectors made from stainless steel, they perform better than most other materials.

Related Reading

- Ellis/Kuhnke Controls

132 Lewis Street Unit A-2, Eatontown, N.J. 07724

Phone: 1-800-221-0714

Fax: 732-291-8154

Email: Info@ekci.com

- Home Pneumatic Controls Technical Info CAD Drawings Contact Us Pneumatic Timers Blog Site Map