The Five Most Important Pneumatic Control System Components

It is important to take the time and learn about the specific parts of a pneumatic control system. Doing this work ensures that you use the correct parts to fill integral roles within your system. A pneumatic control system uses pressurized gas to enable motion in systems. When using improper components, it is difficult, if possible, to have systems running at optimal performance. Below, we want to highlight the most integral components within a pneumatic control system.

Pneumatic Cylinders/Actuators – an actuator is a mechanical device tasked with producing force via compressed air. When a cylinder becomes actuated, compressed air begins to enter tubes at the end of the piston. Once this happens, it imparts a force on the piston, which causes it to move.

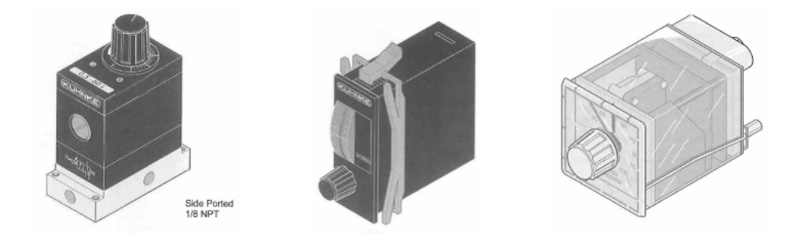

Pneumatic Valves – these devices are an integral part of controlling airflow. Without pneumatic valves, a pneumatic control system would not run efficiently.

Pneumatic Tubing – tubing functions as a hose that transmits pressurized air to other devices, such as actuators, tools, and valves.

Pneumatic Fittings – without fittings, it is not possible to provide control for processes. Use fittings to connect valves and provide leak-free movement of air or gas.

Pneumatic Air Compressor – these devices function as an air exhausting mechanism. The device sucks in outside air and then compresses it to harness gas or air for your process.

Each pneumatic control component is designed to ensure the proper functioning of systems. Each part is as important as the other, so make sure to take the time to pick the right parts for your application.

Related Reading

- Ellis/Kuhnke Controls

132 Lewis Street Unit A-2, Eatontown, N.J. 07724

Phone: 1-800-221-0714

Fax: 732-291-8154

Email: Info@ekci.com

- Home Pneumatic Controls Technical Info CAD Drawings Contact Us Pneumatic Timers Blog Site Map