Understanding the 3-15 PSI Standard in Pneumatic Control Systems

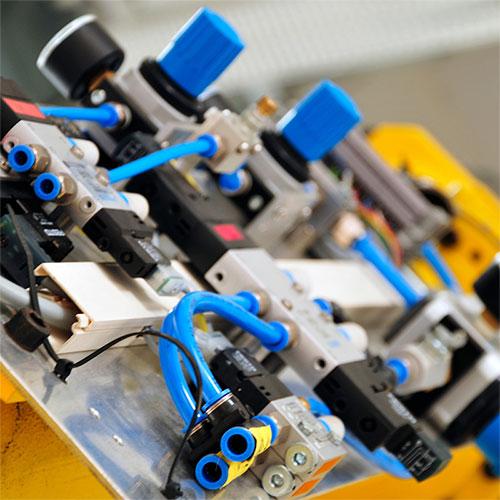

In the diverse world of industrial automation, pneumatic control systems stand out for their reliability and precision. Central to their functionality is the 3-15 PSI standard, a universally acknowledged scale that governs the operation of numerous instruments. While this range is the most common due to its simplicity and efficiency, it's important to note that other ranges exist for specialized applications. However, the 3-15 PSI standard remains the standard for most industrial processes due to its optimal balance between range and resolution.

In the diverse world of industrial automation, pneumatic control systems stand out for their reliability and precision. Central to their functionality is the 3-15 PSI standard, a universally acknowledged scale that governs the operation of numerous instruments. While this range is the most common due to its simplicity and efficiency, it's important to note that other ranges exist for specialized applications. However, the 3-15 PSI standard remains the standard for most industrial processes due to its optimal balance between range and resolution.

Why 3-15 PSI is the Most Common Standard for Pneumatic Control Systems

Choosing 3-15 PSI as the standard operational range isn't arbitrary. It strikes a perfect balance, providing sufficient resolution for control accuracy while maintaining a practical range for most industrial applications. This range is wide enough to allow for precise control yet not so broad as to necessitate overly sensitive equipment, which can be more prone to errors and malfunctions. Specialized applications might call for different ranges, but 3-15 PSI is the practical choice for the broad spectrum of industrial needs.

Understanding the Mechanics

In a typical setup, the indicator, often a specialized pressure gauge, is calibrated not in direct process fluid but in units of clean compressed air pressure from the transmitter. This system clearly represents process pressures, even though the operational mechanics rely on the standard 3-15 PSI range. For instance, in a transmitter calibrated to a 0-250 PSI range, a lack of process pressure results in a 3 PSI air signal, and complete process pressure translates to a 15 PSI air signal. This correlation allows the "receiver" gauge face to display 0-250 PSI while its mechanism operates on the transmitter's 3-15 PSI range output.

The Significance of the Standardized Scale

The 3-15 PSI standardized scale is crucial for industrial efficiency and safety. It simplifies training, maintenance, and troubleshooting, providing a common framework for professionals across various fields. This uniformity in measurement and control enhances system compatibility and reduces the likelihood of errors, contributing to smoother operations and consistent output quality.

Table Illustration and Detailed Explanation

The scale can be broken down as follows:

- 3 PSI = 0%: Indicative of no operation or movement.

- 6 PSI = 25%: A quarter capacity, often marking initial process control stages.

- 9 PSI = 50%: The midpoint is critical for balanced operations.

- 12 PSI = 75%: Signifying a higher state of operation.

- 15 PSI = 100%: Full operational capacity.

Each point on this scale is essential for precisely calibrating pneumatic instruments, affecting everything from flow rate adjustments to temperature control.

Pneumatic Control System Performance

The 3-15 PSI standard is a testament to the blend of simplicity and effectiveness in industrial pneumatic systems. Its widespread adoption underscores its role as a foundational element in industrial automation and control.

For more insights into pneumatic control systems or professional assistance, Ellis/Kuhnke Controls offers a wealth of knowledge and expertise in this specialized field, guiding you through the complexities of modern industrial automation.

Related Reading

- Ellis/Kuhnke Controls

132 Lewis Street Unit A-2, Eatontown, N.J. 07724

Phone: 1-800-221-0714

Fax: 732-291-8154

Email: Info@ekci.com

- Home Pneumatic Controls Technical Info CAD Drawings Contact Us Pneumatic Timers Blog Site Map