A Breakdown of Pneumatic Control Systems

Pneumatic control systems comprise various controls: each system is custom-built depending on many factors, including environment and application. Knowing about the different types of controls helps to understand the possibilities of these systems. Pneumatic controls use compressed air to control and transmit energy. These systems are commonly found in industrial applications, HVAC systems, and various automated processes. Here are the different types of pneumatic controls:

Pneumatic control systems comprise various controls: each system is custom-built depending on many factors, including environment and application. Knowing about the different types of controls helps to understand the possibilities of these systems. Pneumatic controls use compressed air to control and transmit energy. These systems are commonly found in industrial applications, HVAC systems, and various automated processes. Here are the different types of pneumatic controls:

- Valves: These are the primary control elements in a pneumatic system. They control the direction, flow rate, and pressure of the air.

- Directional control valves: Control the flow direction. Examples include 2/2-, 3/2-, 4/2-, and 5/2-way valves.

- Flow control valves: Adjust the flow rate of compressed air. Examples include throttle valves and quick exhaust valves.

- Pressure control valves: Control the air pressure. Examples are pressure regulators, pressure relief valves, and sequence valves.

- Actuators: Convert the energy from compressed air into mechanical motion.

- Linear actuators: Produce linear motion. Examples include cylinders (single or double-acting) and diaphragm actuators.

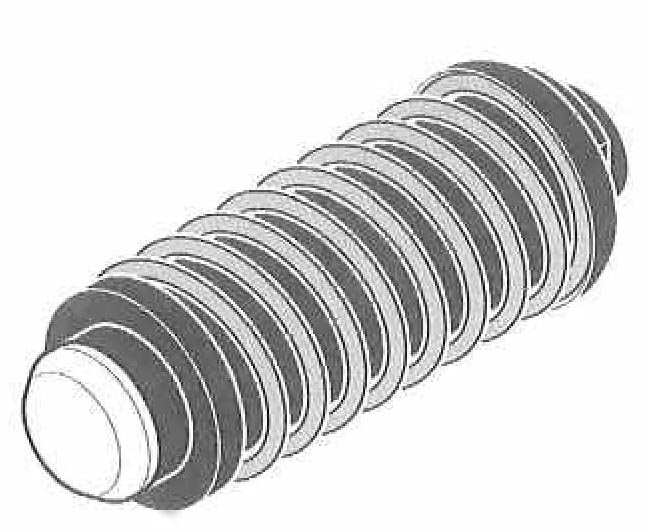

- Rotary actuators: Produce rotational motion. They include vane and piston-type rotary actuators.

- Sensors and Switches: Detect the conditions in the pneumatic system and send feedback.

- Pressure switches: Detect a specific pressure level.

- Flow sensors: They measure the flow rate of the compressed air.

- Limit switches: Detect the end position of actuators.

- Timers and Counters: Used for timing and counting operations in a pneumatic system.

- Logic Elements: Implement basic logic operations like AND, OR, NOT using pneumatic components. These are especially useful when multiple conditions are required to initiate a pneumatic action.

- Relays and Boosters: Enhance or modify the signal strength or quality to make the controls more effective.

- Mufflers and Silencers: Reduce the noise produced when the air is released from the system.

- Filters, Regulators, and Lubricators: (FRLs)

- Filters: Remove contaminants from the compressed air.

- Regulators: Control and maintain the desired air pressure.

- Lubricators: Introduce a fine lubricant mist into the airflow to reduce wear on moving components.

- Connectors and Fittings: Include tubes, hoses, and various fittings to connect components in a pneumatic system.

- Air Preparation Devices: Ensure the quality of the air used in the system. This can involve drying the air, filtering out contaminants, or adding lubrication.

- Controllers and PLCs: Modern pneumatic systems often incorporate electronic controllers or Programmable Logic Controllers (PLCs) to manage and sequence the system's operations.

Related Reading

- Ellis/Kuhnke Controls

132 Lewis Street Unit A-2, Eatontown, N.J. 07724

Phone: 1-800-221-0714

Fax: 732-291-8154

Email: Info@ekci.com

- Home Pneumatic Controls Technical Info CAD Drawings Contact Us Pneumatic Timers Blog Site Map

If you are looking for Pneumatic Controls, Pneumatic Valves then look no further than Ellis/Kuhnke Controls.