Advice for Specifying Pneumatic Valves

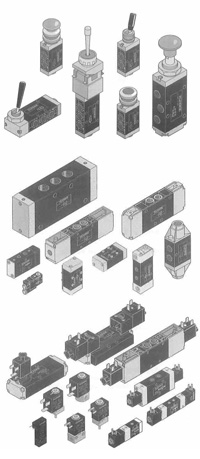

Learning some practical knowledge for how to use and choose pneumatic valves will keep more money in your pocket and will also increase the efficiency of your system. A directional control air valve is one of the essential building blocks for a pneumatic circuit. There is a wide range of different valves available—the number of flow paths, positions, and ports—that all function differently. The most important considerations for choosing directional air valves include the style of mounting, control, and actuation. There are specific guidelines individuals can follow to effectively and efficiently develop pneumatic systems.

Learning some practical knowledge for how to use and choose pneumatic valves will keep more money in your pocket and will also increase the efficiency of your system. A directional control air valve is one of the essential building blocks for a pneumatic circuit. There is a wide range of different valves available—the number of flow paths, positions, and ports—that all function differently. The most important considerations for choosing directional air valves include the style of mounting, control, and actuation. There are specific guidelines individuals can follow to effectively and efficiently develop pneumatic systems.

Pneumatic Controls

One of the first, if not the first, consideration to be made is the amount of flow the valve needs to deliver to the actuator. The measuring of flow is rated as the coefficient of velocity (Cv). As Cv gets higher, so does the flow. Valve sizing charts are the most commonly used means to match cylinders and valves. The table indexes a valve’s Cv against the size of bores, which gives necessary cylinder speed.

In some instances, it is beneficial to convert Cv into standard cubic feet per minute (scfm) or conversely. Cv represents flow capacity at all pressures, and scfm stands for flow at specific temperatures and air pressure. Converting Cv to scfm allows individuals to cover a wide range of pressures. The easiest way to obtain scfm is to divide the valve Cv by matching factors shown on the sizing chart.

Let our team help you solve your pneumatic controls systems problems and to get you pneumatic valves that work for your specific application.

Related Reading

- Top Quality Pneumatic Controls System

From toothpicks to mansions to go-carts to race cars to you name it, on many factory floors you will find our leading brand of pneumatic controls or a state of the art, pneumatic controls system.

- Consuming Compressed Air

- Ellis/Kuhnke Controls

132 Lewis Street Unit A-2, Eatontown, N.J. 07724

Phone: 1-800-221-0714

Fax: 732-291-8154

Email: Info@ekci.com

- Home Pneumatic Controls Technical Info CAD Drawings Contact Us Pneumatic Timers Blog Site Map