Using Pneumatic Valves Properly

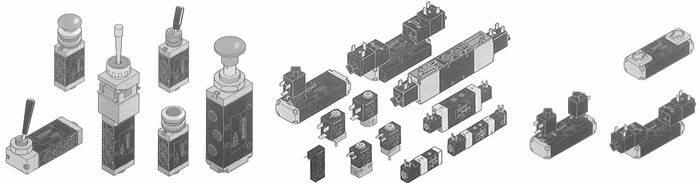

If your company works with pneumatic circuits, then the use of pneumatic valves is essential. They are a requirement. The purpose of pneumatic valves is to direct or blow airflow. Doing this will control the speed or sequence of operations.

Before you use any pneumatic valves for your applications, it is important to understand the basics of how they work. There are many different pneumatics valves to choose. The guidelines for instruction will depend on the model you are using.

Two-way, two-position valves are one type of valves to choose. These pneumatic valves consist of two ports. The ports are connected with a passage which can be blocked or opened. These valves are beneficial because they feature an easy on-off function.

Another type of pneumatic valve is a three-way, two-position valve. This valve features three ports which are through passages within a valve body. If the work you are doing requires high cylinder speeds, then a three-way, two-position valve is more useful than a four-way valve.

Four-way, two-position valves are another type of pneumatic valve. These valves feature four or five ports. If you are using the five port version, you will be provided with different valve shapes such as two separate exhaust or pressure ports.

The last type of standard pneumatic valve is the four-way, three-position valve. These kind of valves are also available with five ports. The center of these valves has multiple functions. It can satisfy system requirements like locking an actuator or letting it float.

Related Reading

- Brief history of Pneumatics: From Blowguns to Pneumatic Valves & Pneumatic Controls

- Different Types of Pneumatic Valves

- Frequently Asked Questions: Pneumatic Valves

- A Great Combination: Pneumatic Actuator, Pneumatic Timer, Pneumatic Valves, and Pneumatic Indicators

- Directional Control for Pneumatic Valves

- Ellis/Kuhnke Controls

132 Lewis Street Unit A-2, Eatontown, N.J. 07724

Phone: 1-800-221-0714

Fax: 732-291-8154

Email: Info@ekci.com

- Home Pneumatic Controls Technical Info CAD Drawings Contact Us Pneumatic Timers Blog Site Map