Pneumatic Control Systems in the Food Industry

Understanding Pneumatic Counters & Pneumatic Timers in Food Processing

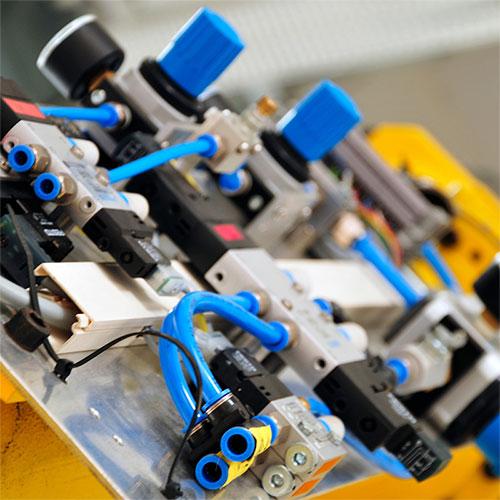

In food production, pneumatic control systems harness compressed air to power machinery and processes. These systems are crucial in sealing, sorting, handling, and direct food processing like vacuum tumbling and mixing. Utilizing pneumatics allows the food industry to achieve precise control, automation, and efficiency. For example, in vacuum sealing, pneumatic systems remove air from packaging, preserving the food's freshness in sorting systems, and controlled air jets direct food items into different channels based on size, weight, or other criteria. These applications underscore the versatility and importance of pneumatic technology in food processing.

In food production, pneumatic control systems harness compressed air to power machinery and processes. These systems are crucial in sealing, sorting, handling, and direct food processing like vacuum tumbling and mixing. Utilizing pneumatics allows the food industry to achieve precise control, automation, and efficiency. For example, in vacuum sealing, pneumatic systems remove air from packaging, preserving the food's freshness in sorting systems, and controlled air jets direct food items into different channels based on size, weight, or other criteria. These applications underscore the versatility and importance of pneumatic technology in food processing.

The Vital Role of Pneumatics in Food Production

What sets pneumatic control systems apart and makes them critical in the food industry? The answer lies in their unique advantages.

- Smooth and Gentle Handling: The gentle movement of pneumatic actuators is ideal for handling delicate food items, ensuring they remain intact and undamaged throughout processing and packaging.

- Enhanced Safety: Pneumatic systems eliminate electrical hazards, reducing the risk of sparks and electrical malfunctions, which is especially important in environments with high moisture or flammable substances.

- Maintaining Hygiene: Designed to meet stringent hygiene standards, pneumatic systems can operate in sterile environments without contamination risks. Components are crafted from materials that withstand frequent cleaning and sanitization.

- Operational Efficiency: These systems can run continuously and manage high volumes, boosting overall productivity. Their reliability and durability mean fewer breakdowns and maintenance issues, ensuring consistent and efficient operations.

Transformative Impact on the Food Industry

Integrating pneumatic control systems doesn't just bring improvements; it revolutionizes the food industry.

- Boosting Production Efficiency: Automation and precise control reduce the need for manual labor, speeding up processes and increasing throughput. Automated systems can sort and package thousands of items per hour, vastly outpacing human capabilities.

- Enhancing Product Quality: Gentle handling and precise control maintain food products' integrity and quality, leading to higher customer satisfaction and a better product.

- Elevating Safety Standards: Pneumatics minimize risks associated with electrical systems, creating safer working conditions and reducing the likelihood of accidents.

- Driving Cost-Effectiveness: Despite the initial investment, the long-term benefits of reduced labor costs, improved efficiency, and lower maintenance expenses contribute to overall savings.

Pneumatic Systems: The Preferred Choice

What makes pneumatic systems the favored solution in food processing? Several factors contribute to their popularity.

- Suitability for Sterile Environments: Pneumatic systems are ideal for cleanroom settings. They meet the hygiene standards necessary for food processing since they can be cleaned and sanitized easily.

- Versatility and Adaptability: These systems can be tailored to various applications, from packaging to direct food processing, efficiently handling different food products and processing requirements.

- Reliability and Durability: Pneumatic components are designed for longevity. They are less prone to wear and tear, resulting in less downtime and maintenance. This reliability ensures continuous operation, which is crucial for high-volume production and gives you confidence in your long-term investment.

Optimizing Pneumatic Counters & Pneumatic Timers

Pneumatic control systems are indispensable in the food industry, offering significant efficiency, safety, and product quality advantages. By investing in advanced pneumatic technologies and maintaining rigorous standards, the food industry can continue to benefit from these systems, ensuring high-quality production and processing while upholding safety and hygiene standards. As pneumatic technology evolves, the future of food processing looks increasingly promising, with enhanced capabilities and innovations on the horizon.

Related Reading

- Ellis/Kuhnke Controls

132 Lewis Street Unit A-2, Eatontown, N.J. 07724

Phone: 1-800-221-0714

Fax: 732-291-8154

Email: Info@ekci.com

- Home Pneumatic Controls Technical Info CAD Drawings Contact Us Pneumatic Timers Blog Site Map