Knowing your Pneumatic Actuator helps in getting the proper Pneumatic Timer

When thinking of an actuator, one can think about a motor; however, actuators are only used to control or move a mechanism/system. All actuators need timers so that they can work efficiently. Different types of actuators require different energy sources, but all need external energy. Energy sources include: electric, hydraulic, or pneumatic. The type of energy that is picked is almost completely dependent on the environment and type of work that is being done. For instance, if you are working with gases or substances that are flammable, electric actuators could potentially lead to tragedy. An actuator's purpose is to help control systems that affect an environment. Some of the most common actuator types include:

Round Line: This type has non-repairable cylinders, but they are extremely hard working and long lasting. They are rather popular because of their affordability. They are made with different bore sizes and mounting styles, which allows for optimal performance. Be mindful with round lines because for certain jobs they require external guiding.

Rotary Actuator: If rotary motions are needed, this is the optimal actuator. It is important to note that there are two types of rotary actuators: rack and pinion designs and Vane types. The Vane types do not have any backlash, but that limits their rotation to 270 degrees. Rack and pinion provide more rotation while not needing external shaft seals. They also boast low friction and low breakaway.

Rodless slide: rodless slides use magnets to help self-guided motions. This helps to save space (roughly 50%). Side and mount loads are possible with these rodless slide. The weight limit for these devices is not great, and so for heavy loads you will want to use external shock absorbers.

Narrow profile air tables: When looking for completely accurate load guiding, this is the tool you should reach for. The high precision is possible as a result of a recirculating ball rail.

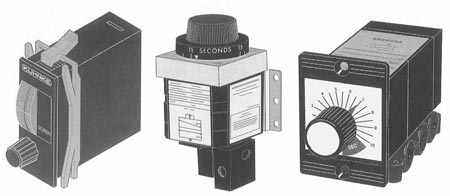

Regardless of the actuator you get, you will need to get other components to help optimize performance. When using a pneumatic actuator you will want to also have the proper pneumatic timer: one that can handle the work that you are doing. This includes, power, performance, and fit. In order to get the proper pneumatic timer, one must know exactly what type of actuator is being used. Get the correct pneumatic timer and pneumatic controls for your actuator.

Related Reading

-

Pneumatic Actuator Types

A pneumatic actuator is a tool that converts compressed air into mechanical motion. -

Different Pneumatic Actuator Types

There are many different types of pneumatic actuators. Each is created to fulfill a specific function, so each has its own pros and cons. -

A Great Combination: Pneumatic Actuator, Pneumatic Timer, Pneumatic Valves, and Pneumatic Indicators

A motor that is used to move/control the mechanics of a system is called an actuator. An actuator can only work when it has a consistent energy source.

- Ellis/Kuhnke Controls

132 Lewis Street Unit A-2, Eatontown, N.J. 07724

Phone: 1-800-221-0714

Fax: 732-291-8154

Email: Info@ekci.com

- Home Pneumatic Controls Technical Info CAD Drawings Contact Us Pneumatic Timers Blog Site Map