Fault Detection and Diagnosis (FDD) for Pneumatic Valves

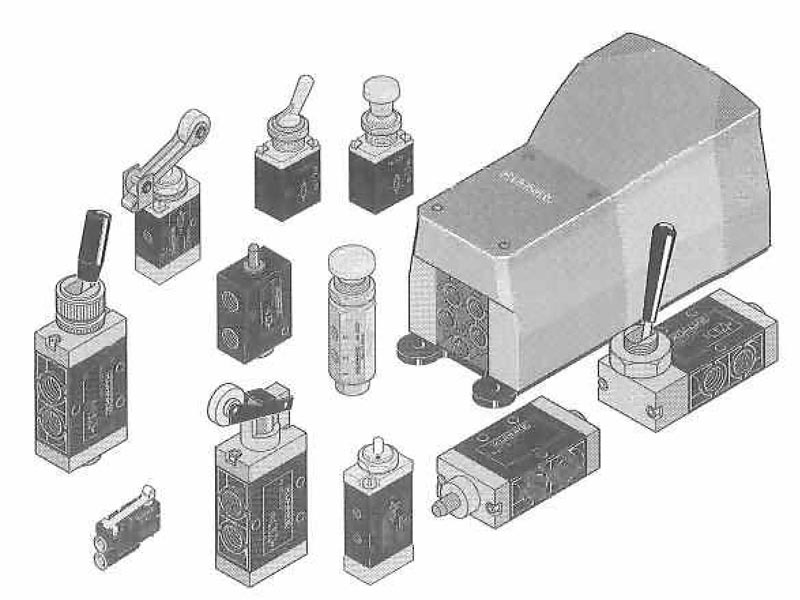

Pneumatic valves are mechanical devices used to control the flow of air or other gases in various industrial and mechanical systems. Like any mechanical component, pneumatic valves can experience failures or problems that can disrupt the system's operation.

Pneumatic valves are mechanical devices used to control the flow of air or other gases in various industrial and mechanical systems. Like any mechanical component, pneumatic valves can experience failures or problems that can disrupt the system's operation.

Some common ways in which pneumatic valves can fail include:

Stuck valve: A stuck valve cannot open or close properly, preventing air or gas flow through the system. Various factors, such as debris or corrosion in the valve, or problems with the actuator or control system, can cause this.

Leaking valve: A leaking valve allows air or gas to escape from the system, which can reduce the system's efficiency and potentially cause other problems. Damaged or worn seals or problems with the valve body or other components can cause leaks.

Failed actuator: The actuator is the pneumatic valve component responsible for moving the valve to open or close. If the actuator fails, the valve will be unable to function properly. Various factors, such as wear and tear, corrosion, or problems with the control system, can cause actuator failures.

Control system failure: The control system is responsible for activating and deactivating the valve based on the system's needs. If the control system fails, the valve may not open or close as it should, disrupting the system's operation.

Overall, there are various ways in which pneumatic valves can fail, significantly impacting the system's operation. Regular maintenance and monitoring can help to identify and prevent these failures.

How to Best Detect Faults within Pneumatic Valves and How to Diagnose Them

Fault detection and diagnosis (FDD) is an important aspect of maintenance and repair in various industrial and mechanical systems. One approach to FDD is using an adaptive neuro-fuzzy inference system (ANFIS).

ANFIS is a type of artificial intelligence system that combines the principles of fuzzy logic and neural networks. It models complex systems and makes predictions or decisions based on input data.

In the context of pneumatic valves, ANFIS can detect and diagnose faults by analyzing the valve's performance data and identifying deviations from normal behavior. For example, ANFIS could identify problems with valve function, such as stuck or leaking valves, based on input data such as pressure, flow rate, and valve position.

One advantage of using ANFIS for FDD in pneumatic valves is its ability to handle uncertainty and imprecision in the data. Fuzzy logic allows ANFIS to make decisions based on fuzzy sets and rules rather than precise values, which can be useful in situations where data is incomplete or unreliable.

Overall, using ANFIS for FDD in pneumatic valves can improve the reliability and efficiency of these systems by allowing for the early detection and diagnosis of problems. As ANFIS technology advances, it will likely be increasingly used in various FDD applications.

Related Reading about Pneumatic Valves

- Ellis/Kuhnke Controls

132 Lewis Street Unit A-2, Eatontown, N.J. 07724

Phone: 1-800-221-0714

Fax: 732-291-8154

Email: Info@ekci.com

- Home Pneumatic Controls Technical Info CAD Drawings Contact Us Pneumatic Timers Blog Site Map