1-800-221-0714

Air Preparation and Pneumatic Valves

All compressed air systems need a safe and precise method of controlling actuators that are unique to specific accouterment. For this to happen, air must go through preparations. A pressure relief valve is designed to control pressure at inlet ports. This is done by exhausting the pressure to the atmosphere. A relief valve is then used to help receivers and air storage devices. Going through this process prevents any excess in pressurization. The relief valve is frequently called a safety valve because of what they do.

- 1The purpose of pressure regulation in a pneumatic system is to limit the downstream pressure by blocking pressure at the inlet. These devices are necessary for the air preparation stage, while also being able to control motors and cylinders.

- In some cases, many staged pressure reductions are necessary. This is the case when working with a big, centralized compressor that is feeding multiple workstations. Regulators control the pressure in the main distribution grid, but it can also be set to an FRL on each machine/workstation.

- Pressure regulators are sometimes used to control the pressure of single actuators (inline regulator or a work-port mounted version). These devices are small and are responsible for checking the reverse flow. It is essential for users to maintain a set pressure differential that is between two ports. Do not just maintain downstream pressure.

Pneumatic Controls

- Directional Control for Pneumatic Valves

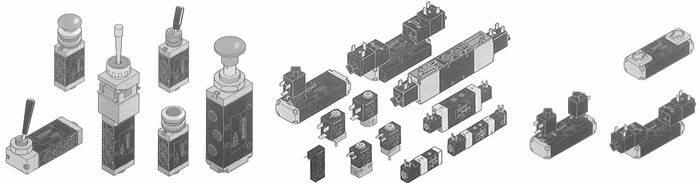

- Different Types of Pneumatic Valves

- Tips for Selecting Directional Pneumatic Valve ControlsSelecting the correct directional pneumatic valves for your application can be difficult. There are many options for valves on the market, and that can give someone choice overload.

- Ellis/Kuhnke Controls

132 Lewis Street Unit A-2, Eatontown, N.J. 07724

Phone: 1-800-221-0714

Fax: 732-291-8154

Email: Info@ekci.com

- Home Pneumatic Controls Technical Info CAD Drawings Contact Us Pneumatic Timers Blog Site Map

If you are looking for Pneumatic Controls, Pneumatic Valves then look no further than Ellis/Kuhnke Controls.