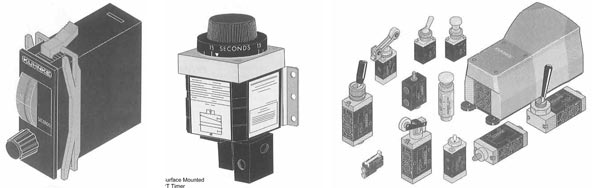

A Great Combination: Pneumatic Actuator, Pneumatic Timer, Pneumatic Valves, and Pneumatic Indicators

A motor that is used to move/control the mechanics of a system is called an actuator. An actuator can only work when it has a consistent energy source. There are five types of energy that can be used with actuators: electric, hydraulic fluid, pneumatic, magnetic, and mechanical. The energy, regardless of source, is used to put the actuator into motion. You can find actuators that are software based or human based. The first actuation systems can be traced back to World War 2. Xhiter Anckeleman created the first pneumatic and hydraulic systems in 1938. Anckeleman had an extensive knowledge of engines and breaks, and he wanted to invent better breaks. He wanted to create breaks that both work better and breakdown less. Since its initial invention in the late 1930s, so many technological advances have been made, including the creation of mechanical, magnetic, and electrical actuators.

A magnetic actuator is used in commercial applications. These actuators are usually lighter and more compact than other actuators. Despite their size, they are rather powerful. They also use SMMs (shape memory materials).

A mechanical actuator works by tuning a rotary motion into a linear one. This is how the actuator is able to create movement. These actuators are heavy and bulky because it requires gears, chains, pulleys, and rails.

A motor powers an electrical actuator. The motor turns electrical energy into mechanical torque. Most commonly you can find these actuators being used in multi-turn valve. The device does not require any oil, and so it the cleanest and easiest to use.

For pneumatic actuators, energy is created through the use of vacuums/compressed air. These actuators work in both a linear and rotary motion. These actuators have the quickest response time of any actuator. It can be stopped and started quickly because it does not require reverse storage for operation. The force that is generated from these devices is large, and this is done with almost no pressure changes.

Hydraulic systems are with ether fluid or cylinder motors. The hydraulic power is responsible for the mechanical operation. This actuator can be moved in linear, rotary, and oscillatory motions. These actuators are arguably the strongest on the market because of waters difficulty to compress. It does, however, have a limited acceleration.

Pneumatic Valves

You must acquire an actuator and components that will work seamlessly with the main device. That means, if you are getting a pneumatic actuator, you should be getting a pneumatic timer, pneumatic valves, and pneumatic indicators.

Related Reading

-

Pneumatic Actuator Types

A pneumatic actuator is a tool that converts compressed air into mechanical motion. -

Different Pneumatic Actuator Types

There are many different types of pneumatic actuators. Each is created to fulfill a specific function, so each has its own pros and cons. -

Knowing your Pneumatic Actuator helps in getting the proper Pneumatic Timer

When thinking of an actuator, one can think about a motor; however, actuators are only used to control or move a mechanism/system.

- Ellis/Kuhnke Controls

132 Lewis Street Unit A-2, Eatontown, N.J. 07724

Phone: 1-800-221-0714

Fax: 732-291-8154

Email: Info@ekci.com

- Home Pneumatic Controls Technical Info CAD Drawings Contact Us Pneumatic Timers Blog Site Map